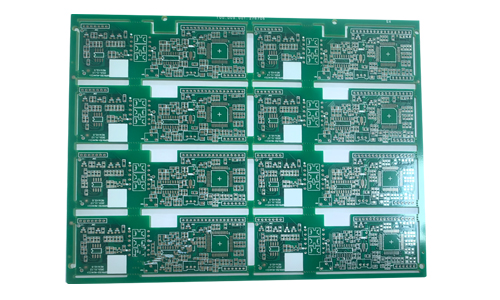

The 4-layer HASL module PCB is a high-performance PCB developed for power management and modular design.

Four-Layer Tin-Spraying Module Power PCB Product Introduction

1.Product Overview

The 4-layer HASL module PCB is a high-performance PCB developed for power management and modular design.. Its four-layer structure provides better electrical performance and signal integrity, and the HASL surface treatment ensures good solderability, which is suitable for a variety of high-power and high-frequency applications.

2.Product Features

1.Four-layer design

2.The 4-layer structure enables complex circuit layouts and provides higher signal integrity and electrical performance.

3.HASL surface treatment

4.The HASL process is used to provide good solderability, suitable for a variety of welding processes, and ensure reliable connections.

5.Good electrical performance

6.Design optimization ensures signal integrity, suitable for applications with high requirements for power and signal quality.

7.Excellent heat dissipation performance

8.Suitable for high-power applications, can effectively reduce the temperature of the circuit board, and improve the stability and reliability of the system.

9.Durability

10.High-quality materials are used, with good corrosion resistance and oxidation resistance, suitable for various environmental conditions.

3.Application Areas

Power management

Suitable for power management systems such as switching power supplies and DC-DC converters.

Industrial equipment

Widely used in industrial control, automation equipment and other fields.

Communication equipment

Suitable for high-frequency communication equipment such as base stations and communication modules.

Consumer electronics

Provide stable power support in high-performance consumer electronics products.

4.Technical Specifications

|

Number of layers |

4 layers |

Minimum aperture |

0.2 mm |

|

Copper thickness |

1 oz inside and outside |

Minimum line width |

0.1 mm |

|

Board |

FR-4 KB6160 |

Surface treatment |

HASL |

|

Solder mask color |

green oil with white text |

/ |

/ |

5.Production Process

1.Design phase

2.Use professional PCB design software for circuit design and layout.

3.Material selection

4.Select the appropriate substrate and copper thickness according to customer needs.

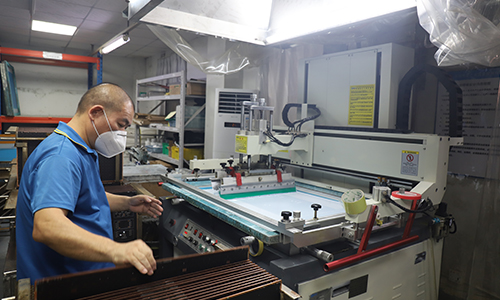

5.Manufacturing phase

6.Perform processes such as photolithography, etching, drilling, and lamination.

7.Surface treatment

8.Use HASL process for surface treatment to ensure good solderability and conductivity.

9.Testing phase

10.Conduct electrical tests and reliability tests to ensure product quality.

11.Delivery phase

12.After completion, pack and ship to ensure that the product reaches the customer safely.

|

|

The 4-Layer HASL Power Module PCB combines advanced layer stackup design, robust thermal management, and industry-leading durability to meet the rigorous demands of modern power electronics. Key strengths include:

High-Current Support: 2oz copper layers and optimized trace layouts enable stable power delivery up to 30A.

Thermal Resilience: Thermal vias and enhanced copper coverage reduce hotspot formation, ensuring reliability in high-load scenarios.

Broad Compatibility: Suitable for industrial, automotive, and consumer applications, withstanding extreme temperatures and humidity.

Ideal for engineers seeking a cost-effective yet high-performance solution, this PCB is a cornerstone for efficient power conversion, motor control, and energy management systems. Its compliance with international standards (IPC, UL) further guarantees quality and safety in mission-critical environments.

FAQ

1.Q: What files are used in PCB production?

A: PCB production requires Gerber files and PCB manufacturing specifications, such as the required substrate material, finished thickness, copper layer thickness, solder mask color, and design layout requirements.

2.Q: When can I get a quotation after I provide Gerber, product process requirements?

A: Our sales staff will give you a quotation within 1 hour.

3.Q: How to resolve short circuits and open circuits in power PCB?

A: Short circuits and open circuits are usually caused by circuit aging or manufacturing defects, and need to be resolved through careful inspection and professional repair methods.

4.Q: How long does it generally take to deliver HDI high-frequency PCB?

A: We have raw material inventory (such as RO4350B, RO4003C, etc.), and our fastest delivery time can be 3-5 days.