The 16-layer industrial control test board is an indispensable core component in the industrial control system.

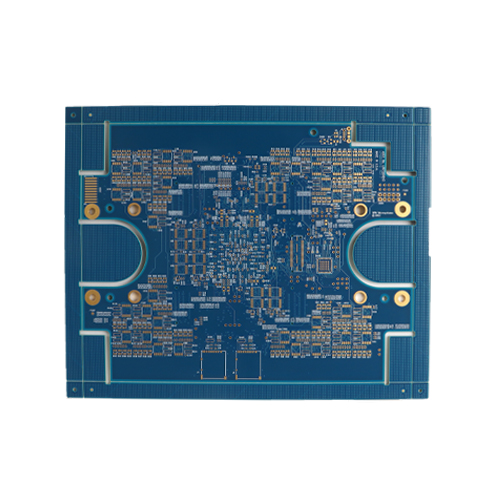

16 layer Industrial Control Test Motherboard Product Introduction

The16-layer industrial control test board is an indispensable core component in the industrial control system. They offer high performance, high reliability and flexible scalability to meet the needs of complex industrial applications. The following is a detailed introduction of our 16-layer industrial control test board:

|

|

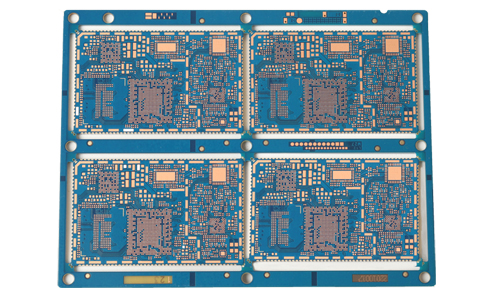

1.Product Overview

Our 16-layer industrial test motherboards are designed in multiple layers to support complex circuit layouts and high-density component installations. They are widely used in industrial automation, robot control, embedded systems, data acquisition and test equipment.

2. Technical Specifications

| Number of layer | 16 | Minimum line width and line spacing | 0.1/0.1mm |

| Thickness of plating | 2.0mm | Minimum aperture | 0.2 |

| Board material | S1000-2M | Surface treatment | Heavy gold 3U |

| Copper thickness | Inner 1OZ Outer 1.5OZ | Process points | Impedance control + countersunk hole + resin jack |

3. Product Features

High density interconnect: The 16-layer design provides additional wiring layers to support high density circuit design, suitable for complex industrial control systems.

Excellent electrical performance: High quality materials and advanced manufacturing processes ensure excellent electrical performance and signal integrity.

Good thermal management: The multi-layer design helps to dissipate heat and ensure stable operation of the equipment under high loads.

High reliability: Strict quality control and testing process to ensure high reliability and long service life of products.

Flexible design: Support a variety of surface treatments and solder resistance colors to meet different customer design needs.

4. Application Field

Industrial automation: industrial control system, PLC, DCS, etc

Robot control: robot controller, sensor interface, etc

Embedded Systems: Various types of embedded controllers and computing platforms

Data acquisition and test: data acquisition card, test equipment, etc

Energy management: smart grid, energy monitoring system, etc

5. Manufacturing Process

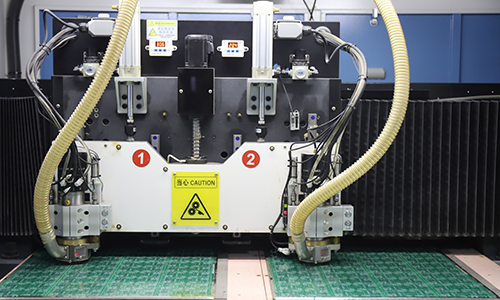

We use the most advanced manufacturing processes and equipment to ensure that every 16-layer industrial test board meets strict quality standards. Our processes include:

High precision laser drilling: to ensure the accuracy and consistency of microholes

Automated Optical Inspection (AOI) : Detects circuit board defects and deviations

X-Ray inspection (X-ray) : detects the internal structure of the multilayer panels to ensure the reliability of the alignment and connection between layers

Electrical testing: Ensure that the electrical performance of each PCB meets the design requirements

6. Quality Control

We implement a comprehensive quality control system, from raw material testing to finished product testing, every link is subject to strict quality inspection. We use international standard testing methods, such as electrical performance testing, functional testing, environmental testing, etc., to ensure that every PCB meets customer requirements.

|

|

7.Conclusion

Our 16-layer industrial test boards are used in a wide range of demanding industrial control systems thanks to their high density interconnect, excellent electrical performance, good thermal management and high reliability. We are committed to providing our customers with the highest quality products and services to help them succeed in a highly competitive market.

FAQ

1.Q: When can I get a quotation after I provide Gerber, product process requirements?

A: Our sales staff will give you a quotation within 1 hour.

2.Q: How many employees do you have in your factory?

A: More than 500.

3.Q: How to solve the interlayer alignment error issue in automotive PCB production?

A: Interlayer misalignment errors are usually caused by inaccurate positioning systems and can be resolved by improving positioning accuracy.

4.Q: Can you provide samples?

A: We have the capability to quickly prototype PCBs and offer comprehensive technical support.