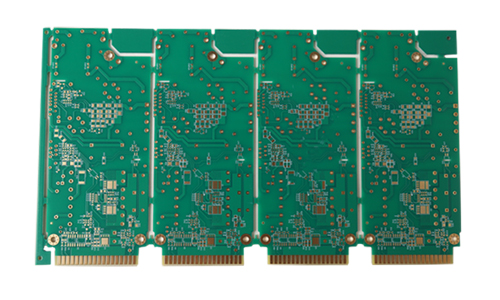

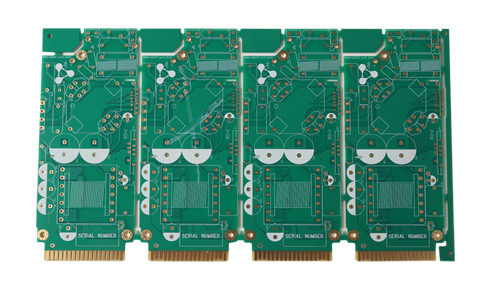

The four-layer server power gold finger module board is a high-performance PCB (printed circuit board) designed for server power management.

Power Goldfinger Module Board For ServerProduct Introduction

|

|

1.Product Overview

The four-layer server power gold finger module board is a high-performance PCB (printed circuit board) designed for server power management. The module board adopts a gold finger interface to ensure the stability and reliability of the power connection, and is widely used in data centers, cloud computing, and high-performance computing.

2.Main Features

Four-layer design:

Adopting a four-layer PCB structure, it optimizes power distribution and signal integrity.

Effectively reduces electromagnetic interference (EMI) and improves the stability of power management.

Gold finger interface:

The gold finger part uses highly conductive materials to ensure good electrical contact.

The design complies with industry standards and is suitable for power connections that are frequently plugged and unplugged.

High power carrying capacity:

The design can carry high power loads and is suitable for the needs of high-performance servers.

High-temperature materials are used to ensure safe operation under high load conditions.

Modular design:

Supports modular design, which is easy to integrate with other power management modules.

Facilitates rapid replacement and maintenance, improving system availability.

Multiple surface treatments:

Provide multiple surface treatment options, such as ENIG, HASL, etc. to meet different customer needs.

Adapt to different welding processes and environmental requirements.

3.Technical Specifications

| Number of layers | 4 layers | Ink color | green oil white text |

| Material | FR-4, S1000 | Minimum line width/line spacing | 0.1mm/0.1mm |

| Thickness | 1.6mm | Gold finger thickness | 30 wheat |

| Copper thickness | inner 0.5 outer layer 1OZ | Surface treatment | immersion gold |

4.Application Areas

Server power supply: used for various types of server power modules.

Data center: supports high-density power management solutions.

Cloud computing: suitable for cloud servers and virtualization environments.

High-performance computing: meets the power needs of high-performance computing clusters.

|

|

5.Conclusion

The four-layer server power gold finger module board is a high-performance and reliable product designed to meet the power management needs of modern servers. Its gold finger interface and modular design make it an ideal choice for efficient power solutions, providing stable power support for data centers and high-performance computing.

FAQ

Q: How many employees do you have in your factory?

A: More than 500.

Q: Are the materials you use environmentally friendly?

A: The materials we use are in accordance with ROHS standard and IPC-4101 standard.

Q: Can gold finger PCB corrode due to flux?

A: Flux used in wave soldering may corrode gold fingers, resulting in solder marks on the gold fingers. This situation is usually caused by the use of unclean flux, which has strong penetrating ability and may lead to the corrosion of gold fingers. Solutions to this problem include improving soldering processes, using more appropriate gold finger protective fluxes, or carrying out proper post-processing after soldering to reduce the corrosion of flux on gold fingers.

Q: Can you provide samples?

A: We have the ability to quickly proof-sample PCB and provide comprehensive technical support.