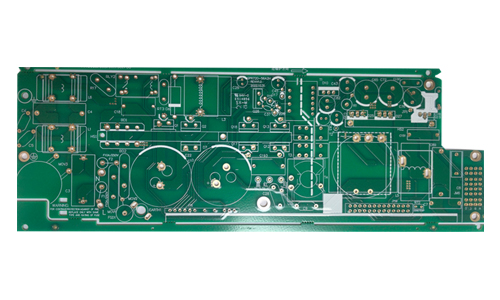

Double-sided immersion gold thick copper power PCB is a high-performance printed PCB designed for high-power and high-frequency applications.

Double-Sided Immersion Gold Thick Copper Power PCB Product Introduction

1.Product Overview

Double-sided immersion gold thick copper power PCB is a high-performance printed PCB designed for high-power and high-frequency applications. Its double-sided circuit design and immersion gold surface treatment provide superior conductivity and durability, which is very suitable for applications with high requirements for power management and signal integrity.

2.Product Features

1.Double-sided design

2.With double-sided circuit layout, it is easy to realize complex circuit connections and improve design flexibility.

3.Thick copper layer

4.The copper thickness is usually 2 oz (about 70 μm) or higher, which can carry large currents and is suitable for high-power applications.

5.Immersion gold surface treatment

6.The immersion gold process is used to provide excellent conductivity and wear resistance, which is suitable for high-frequency signal transmission and reduces contact resistance.

7.Excellent heat dissipation performance

8.The thick copper layer design helps to quickly dissipate heat, reduce circuit board temperature, and improve system stability.

9.Durability

10.High-quality materials are used, with good corrosion resistance and oxidation resistance, suitable for various environmental conditions.

3.Application Areas

Power management

Suitable for power management systems such as switching power supplies and DC-DC converters.

Industrial equipment

Widely used in industrial control, automation equipment and other fields.

Communication equipment

Suitable for high-frequency communication equipment such as base stations and communication modules.

Consumer electronics

Provide stable power support in high-performance consumer electronics products.

4.Technical Specifications

| Number of layers | 2 layers | Minimum aperture | 0.2 mm |

| Copper thickness | 2 oz | Minimum line width | 0.1 mm |

| Board material | FR-4 KB6160 | Surface treatment | ENIG |

| Solder mask color | green oil with white text | / | / |

5.Production Process

1.Design phase

2.Use professional PCB design software for circuit design and layout.

3.Material selection

4.Select the appropriate substrate and copper thickness according to customer needs.

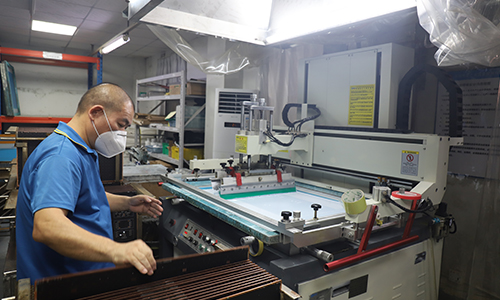

5.Manufacturing phase

6.Perform processes such as photolithography, etching, drilling, and lamination.

7.Surface treatment

8.Use immersion gold process for surface treatment to ensure good conductivity and durability.

9.Testing stage

10.Conduct electrical tests and reliability tests to ensure product quality.

11.Delivery stage

12.Packing and delivery after completion to ensure that the product reaches the customer safely.

|

|

6.Conclusion

Double-sided immersion gold thick copper power PCB is an ideal choice for high-performance power solutions and is suitable for a variety of high-power and high-frequency applications. With its superior electrical performance, heat dissipation capability and durability, it can meet the stringent requirements of modern electronic devices for power supply.

FAQ

1.Q: How many employees do you have in your factory?

A: More than 500.

2.Q: Are the materials you use environmentally friendly?

A: The materials we use are in accordance with ROHS standard and IPC-4101 standard.

3.Q: What are the common causes of short circuits in power PCB and how can they be resolved?

A: Possible causes of short circuits in power PCB include improper pad design, inappropriate component orientation design, and automated insertion of bent leads. Short circuits can be prevented by changing round pads to oval, increasing the distance between pads, modifying component orientation to be perpendicular to the solder wave, and ensuring that solder joints are more than 2mm away from the trace.

4.Q: Do you have laser drilling machines?

A: We have the most advanced laser drilling machine in the world.