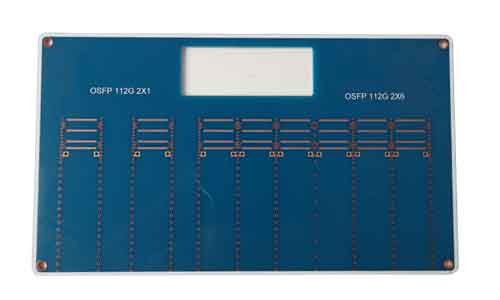

2-layer PCB (Printed Circuit Board) for air conditioner is a circuit board designed for air conditioning system, mainly used to control and manage various functions of air conditioner, such as temperature adjustment, wind speed control and fault monitoring.

PCB Electronic Component For Air Conditioner Product Introduction

|

|

1.Product Overview

2-layer PCB (Printed Circuit Board) for air conditioner is a circuit board designed for air conditioning system, mainly used to control and manage various functions of air conditioner, such as temperature adjustment, wind speed control and fault monitoring. Due to its simple structure and low cost, it is widely used in home and commercial air conditioning equipment.

2.Product Features

Double-layer design

The 2-layer structure simplifies the circuit design and facilitates wiring and assembly.

Suitable for control systems with relatively simple functions, reducing production costs.

High reliability

High-quality materials and processes are used to ensure the stability of the circuit board in high temperature and humid environments.

Rigorous testing ensures reliability in long-term use.

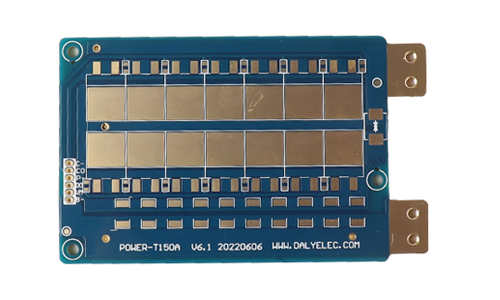

Good heat dissipation performance

The heat dissipation requirements are taken into consideration during the design to ensure the normal operation of the circuit board under high load.

Suitable for the working environment of air conditioning equipment, which can effectively prevent overheating.

Easy to maintain

Simple structure, easy to detect and repair, reducing maintenance costs.

Clear identification and layout, convenient for technicians to troubleshoot.

3.Technical Specifications

| Number of layers | 2 layers | Aperture tolerance | PTH +/-3MIL |

| Material | FR-4, S1141 | Ink color | blue oil white characters |

| Thickness | 1.6mm | Surface treatment | ENIG |

| Copper thickness | 1OZ | / | / |

4.Application Areas

Household air conditioning

Used for the control and management of home air conditioning systems to provide a comfortable indoor environment.

Commercial air conditioning

Applied to large air conditioning systems such as shopping malls and offices to ensure efficient temperature control and energy consumption management.

Central air conditioning system

As part of the central air conditioning control unit, it manages the temperature and wind speed of multiple areas.

Manufacturing process

Material selection

Common materials include FR-4, which has good insulation and thermal stability and is suitable for air-conditioned environments.

Printing process

Advanced screen printing and photolithography technology are used to ensure the accuracy and delicacy of the circuit.

Assembly process

Surface mount (SMT) and through-hole mounting (THT) technology are used to ensure the firmness and reliability of components.

5.Quality Control

Strict testing process

Including functional testing, withstand voltage testing and environmental testing, etc., to ensure the quality of each PCB.

Compliance with international standards

Passed ISO9001, IPC-A-600 and other certifications to ensure that the products meet international standards.

|

|

6.Conclusion

The 2-layer PCB circuit board for air conditioning is an indispensable core component in air conditioning equipment. With its simple design and high reliability, it provides a guarantee for the stable operation of the air conditioning system. Choosing the right manufacturer and material can ensure the performance and durability of the PCB and meet the market demand for air conditioning equipment.

FAQ

1.Q: How far is your factory from the nearest airport?

A: About 30 kilometers.

2.Q: What is your minimum order quantity?

A: One piece is enough to place an order.

3.Q: What special issues need to be paid attention to when designing industrial PCBs?

A: Signal integrity issues, ensuring that signals are transmitted on the PCB without distortion.

4.Q: Can you provide samples?

A: We have the capability to quickly prototype PCBs and offer comprehensive technical support.