Its main function is to provide reliable electrical connections and signal transmission for industrial equipment. Compared with 4-layer circuit boards, 6-layer industrial control circuit boards have higher signal integrity, stronger anti-interference ability and greater design flexibility, and are suitable for more complex industrial control applications.

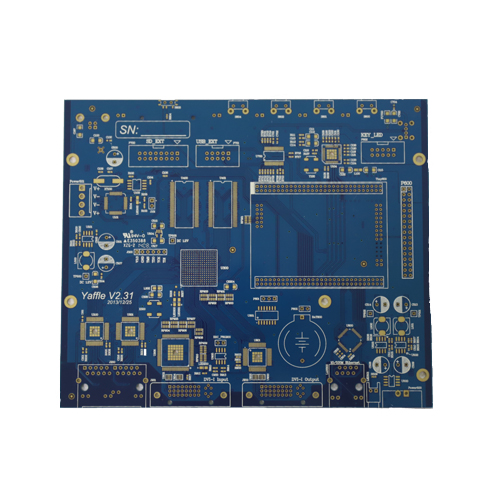

6-layer Industrial Control Circuit Board Product Introduction

|

|

1.Product Overview

The 6-layer industrial control circuit board is a multi-layer printed circuit board (PCB) used in industrial control systems. Its main function is to provide reliable electrical connections and signal transmission for industrial equipment. Compared with 4-layer circuit boards, 6-layer industrial control circuit boards have higher signal integrity, stronger anti-interference ability and greater design flexibility, and are suitable for more complex industrial control applications.

2.Product Main Features

1. Multi-layer structure

The 6-layer industrial control circuit board consists of six conductive layers, usually including four signal layers, one power layer and one ground layer. This multi-layer structure can further reduce signal interference and electromagnetic radiation, and improve the stability and reliability of signal transmission.

2. High-density wiring

Due to the multi-layer design, the 6-layer industrial control circuit board can achieve higher-density wiring, thereby supporting more functions and more complex circuit designs. This is especially important for industrial control systems that need to integrate multiple functions.

3. Excellent thermal management

The 6-layer industrial control circuit board usually adopts high-quality materials and advanced manufacturing processes, and has good thermal management performance. This can effectively reduce the operating temperature of the circuit board and extend its service life.

4. Strong anti-interference ability

Through reasonable interlayer design and shielding measures, the 6-layer industrial control circuit board can effectively resist external electromagnetic interference and ensure the stability and accuracy of signal transmission.

5. Greater design flexibility

The 6-layer industrial control circuit board provides more design space and flexibility, can meet more complex circuit requirements, and support higher functional integration.

3.Application Areas

The 6-layer industrial control circuit board is widely used in the following fields:

Automation control system: such as PLC (programmable logic controller), DCS (distributed control system), etc.

Industrial robot: used to control and drive industrial robots to achieve precise motion control.

Power system: such as substation monitoring, power distribution automation, etc.

Transportation: such as rail transit signal system, intelligent traffic management system, etc.

Energy management: such as control and monitoring of renewable energy systems such as wind power generation and solar power generation.

Medical equipment: such as control of high-precision medical instruments and equipment

4.Technical Specifications

| Number of layers | 6 | Minimum line width and line spacing | 0.1/0.1mm |

| Board thickness | 1.6mm | Minimum aperture | 0.2 |

| Board material | S1000H | Surface treatment | 2U immersion gold |

| Copper thickness | 1OZ inner layer and 1OZ outer layer | Process points | Impedance control + crimping hole |

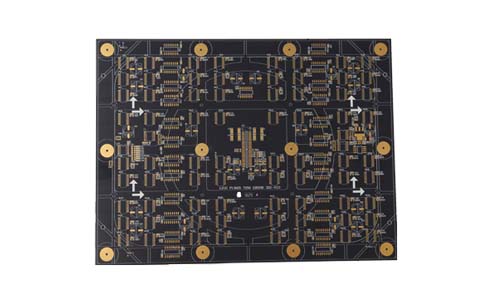

5.Manufacturing Process

The production process of 6-layer industrial control circuit boards includes the following main steps:

1. Design and layout: Use EDA (electronic design automation) software for circuit design and layout.

2. Material selection: Select suitable substrate materials, such as FR4, ceramic substrate, etc.

3. Lamination: Laminate each layer of conductive layer and insulating layer to form a multi-layer structure.

4. Drilling: Use precision drilling equipment to process through holes and blind holes.

5. Plating and etching: Electroplating and etching the drilled circuit board to form a conductive path.

6. Surface treatment: Perform surface treatment such as HASL (hot air leveling), ENIG (chemical nickel plating), etc.

7. Testing and inspection: Electrical testing and appearance inspection of the finished circuit board to ensure quality.

|

|

6.Conclusion

The 6-layer industrial control circuit board has become an indispensable and important part of the industrial control system due to its high-density wiring, excellent thermal management and strong anti-interference ability. Its wide range of applications and superior performance make it popular in the market. It plays a key role in the generation of industrial automation.

If you have any questions or needs about our 6-layer industrial control circuit board products, please feel free to contact us.

FAQ

1.Q: How many employees do you have in your factory?

A: More than 500.

2.Q: How far is your factory from the nearest airport?

A: About 30 kilometers.

3.Q: How to solve the thermal management issue in industrial PCBs?

A: Prevent overheating by Reasonable layout and thermal conductive materials.

4.Q: Can you provide samples?

A: We have the capability to quickly prototype PCBs and offer comprehensive technical support.