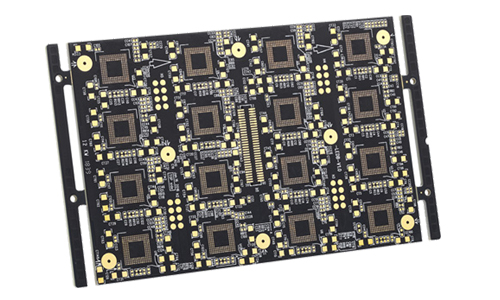

12-layer high-density arbitrary interconnection circuit board (HDI PCB) is an advanced circuit board technology widely used in electronic products, especially in smart phones, tablets, medical devices and automotive electronics.

High Density Interconnect PCB Product Introduction

1.Product Overview

12-layer high-density arbitrary interconnection circuit board (HDI PCB) is an advanced circuit board technology widely used in electronic products, especially in smart phones, tablets, medical devices and automotive electronics. The product achieves smaller size, higher performance and better signal integrity through multi-layer design and high-density interconnection technology.

2.Product Features

1. High-density design

Multi-layer structure: The 12-layer design can integrate more circuits in a limited space.

Micro-aperture: The use of micro-aperture technology supports higher wiring density.

2. Superior electrical performance

Low signal loss: Optimized stacking structure and material selection to reduce the loss in signal transmission.

Good anti-interference ability: Improve the anti-electromagnetic interference ability through reasonable ground layer design and power layer layout.

3. Optimized thermal management

Heat dissipation performance: The use of thermal conductive materials and design ensures the stability and reliability of the equipment under high load.

4. Flexible design options

Arbitrary interconnection: Supports complex circuit design to meet the needs of different products.

Multiple material options: Different substrates can be selected according to customer needs, such as FR-4, polyimide, etc.

3.Technical Parameters

| Number of layers | 12 | Solder mask | black oil and white text |

| Material | TU768 | Minimum aperture | laser hole 0.1mm, mechanical hole 0.15mm |

| Aspect ratio | 6:1 | Line width/line spacing | 2mil/2mil |

| Thickness | 1.0mm | Technical points | 4+N+4 |

| Surface treatment | immersion gold | / | / |

4.Application Areas

Consumer electronics: smart phones, tablets, wearable devices, etc.

Industrial equipment: automatic control systems, sensors, etc.

Medical equipment: monitoring instruments, diagnostic equipment, etc.

Automotive electronics: in-car entertainment systems, navigation systems, etc.

5.Production Process

High-precision manufacturing: using advanced manufacturing equipment and processes to ensure high precision and high reliability of products.

Strict quality control: each production link undergoes strict quality inspection to ensure that the products meet international standards.

|

|

6.Conclusion

The 12-layer high-density arbitrary interconnection circuit board is a high-performance, high-reliability circuit board solution that can meet the needs of modern electronic products for miniaturization, high performance and high density. We are committed to providing customers with quality products and services, helping customers succeed in the fierce market competition.

FAQ

Q:How far is your factory from the airport?

A: 30 km.

Q:What is your MOQ?

A: 1 PCS.

Q: After providing Gerber, product process requirements, when can I get a quote?

A: PCB quotation within 1 hour.

Q:HDI arbitrary interconnection PCB circuit board common problems as follows:

4.1 Soldering defects: Soldering defects are one of the most common problems in HDI circuit board manufacturing, which may include cold welding, solder bridging, solder cracks, etc. Solutions to these problems include optimizing soldering parameters, using high-quality solder and flux, and regularly maintaining soldering equipment.

4.2 Rework problems: Rework is an inevitable process in HDI circuit board manufacturing, especially when defects are found. Correct rework technology can ensure the functionality and reliability of the circuit board. Solutions to rework problems include using appropriate rework equipment, precise defect positioning, and controlling rework temperature and time1.

4.3 Rough hole wall: During the manufacturing process of HDI boards, improper drilling can lead to rough hole walls, affecting the performance of the circuit board. Solutions include using the right drill bit, ensuring the drilling speed is moderate, and optimizing drilling parameters to improve the hole wall quality.

4.4 Plating quality issues: Plating is a key link in the manufacturing process of HDI boards. Improper plating can lead to uneven conductor thickness, affecting the performance of the circuit board. Solutions include surface treatment of the substrate to remove oxides and impurities, and optimizing plating parameters to improve plating quality2.

4.5 Warping issues: Due to the large number of layers of HDI boards, warping problems are prone to occur during the manufacturing process. Solutions include controlling temperature and humidity, and optimizing the design to reduce the risk of warping.

4.6 Short circuit and open circuit: This is one of the most common types of faults. A short circuit refers to an accidental connection between two or more conductors in a circuit that should not be connected; an open circuit refers to a part of the circuit being cut off, resulting in the inability of current to flow.

4.7 Component damage: Component damage is also a common type of failure, which may be caused by overload, overheating, unstable voltage, etc.

4.8 PCB layer peeling: PCB layer peeling refers to the separation between the layers inside the circuit board. This failure is usually caused by improper welding or excessive temperature.