Rigid PCB is widely used in various electronic devices such as mobile phones, computers, home appliances and industrial equipment due to its excellent electrical properties, mechanical strength and durability.

Rigid PCB For Electronic Product Introduction

|

|

1.Product Overview

Rigid PCB is a printed circuit board widely used in electronic products. It has a fixed shape and structure and is usually composed of multiple layers of insulating materials and conductive materials. Rigid PCB is widely used in various electronic devices such as mobile phones, computers, home appliances and industrial equipment due to its excellent electrical properties, mechanical strength and durability.

2.Product Features

1. High strength and stability

Mechanical strength: Rigid PCB has high resistance to bending and impact, suitable for use in harsh environments.

Fixed shape: not easy to deform, suitable for applications requiring precise positioning and connection.

2. Excellent electrical performance

Low signal loss: Good conductivity to ensure the stability and reliability of signal transmission.

High frequency performance: Suitable for high-frequency circuit design to meet the needs of modern electronic products.

3. Multi-layer design

Complex circuit: Supports multi-layer design, enabling more complex circuit layout and space saving.

Higher connection density: Suitable for miniaturized and high-density electronic product design.

4. Heat resistance and corrosion resistance

High temperature tolerance: Able to withstand high temperature welding and working environment, suitable for industrial applications.

Anti-corrosion: Surface treatment can prevent oxidation and corrosion and extend service life.

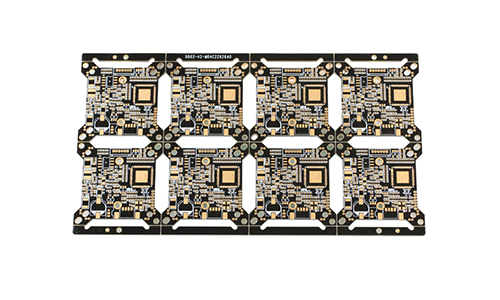

3.Technical Parameters

| Number of layers | 6 layers | Minimum aperture | 0.25mm |

| Board | FR-4 SY1000 | Minimum hole copper | 20um |

| Board thickness | 1.6+/-0.16mm | Surface copper thickness | 1OZ |

| Size | 152mm*84mm | Minimum line width | 0.15mm |

| Minimum line spacing | 0.18mm | Surface treatment | immersion gold |

4.Application Areas

Consumer electronics: mobile phones, tablets, TVs, etc.

Computers: motherboards, graphics cards, hard drives, etc.

Industrial equipment: automation equipment, instruments and meters, control systems, etc.

Automotive electronics: car navigation, entertainment systems, sensors, etc.

5.Production Process

1. Design: Use professional software for circuit design and layout.

2. Plate making: Make photolithography according to the design file.

3. Etching: Remove excess copper layers to form circuit patterns.

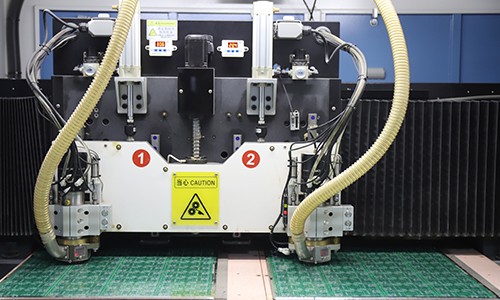

4. Drilling: Drill holes according to design requirements to connect circuits between different layers.

5. Surface treatment: Perform necessary surface treatment to improve welding performance and corrosion resistance.

6. Test: Perform electrical tests to ensure product quality.

|

|

6.Summary

Rigid PCB is an indispensable component of modern electronic products. With its excellent mechanical and electrical properties, it is widely used in various fields. Whether it is consumer electronics, industrial equipment or automotive electronics, rigid PCB can meet the needs of high performance and high reliability.

FAQ

Q: Do You have an office in shanghai or shenzhen that i can visit?

A: We are in Shenzhen.

Q: Will you attend the fair to show your products?

A: We're planning on it.

Q: How long it takes you to provide the designing options for us?

A: 3 days.

Q: Security monitoring PCB signal interference?

A: It is caused by unreasonable wiring, poor ground design or excessive power supply noise. Solutions include optimizing wiring, reasonably allocating ground and power lines, and using shielding layers or filters to reduce noise interference.

Q: Insufficient thermal design of 6-layer PCB?

A: 6-layer PCB circuit board will generate a lot of heat when working. If the thermal design is insufficient, it may cause the circuit board to overheat and affect the normal operation of the circuit. Solutions include adding heat sinks or heat sinks, optimizing the heat dissipation path, and reasonably arranging heat dissipation components.

Q: Poor impedance matching of security monitoring PCB?

A: It causes reflection and loss during signal transmission, affecting circuit performance. Solutions include using impedance calculation tools for impedance matching design, reasonably selecting materials and thickness, and optimizing wiring.