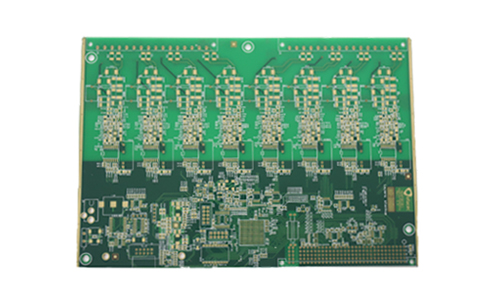

Four-layer solar inverter PCB is a printed circuit board designed for solar inverters, mainly used to convert the DC power generated by solar panels into AC power for home or industrial use.

PCB Fabrication For Solar Inverter Product Introduction

|

|

1.Product Overview

Four-layer solar inverter PCB is a printed circuit board designed for solar inverters, mainly used to convert the DC power generated by solar panels into AC power for home or industrial use. This PCB adopts a four-layer design, which can effectively support complex circuit layout and high-power applications, ensuring the high efficiency and stability of the inverter.

2.Product Features

1. Four-layer design

High-density wiring: The four-layer structure allows for more complex circuit design, suitable for high-power and high-frequency applications.

Signal integrity: Through layered design, signal interference is reduced, and the stability and reliability of the circuit are improved.

2. Excellent electrical performance

High-efficiency conversion: The optimized circuit design ensures efficient DC to AC conversion and maximizes energy utilization.

Low heat loss: The design takes thermal management into consideration and reduces the heat loss of the inverter during operation.

3. High temperature and corrosion resistance

High temperature tolerance: It can withstand the high temperature generated when the inverter is working, ensuring long-term stable operation.

Anti-corrosion material: The use of anti-corrosion material is suitable for various environmental conditions and prolongs the service life of the PCB.

4. Good heat dissipation performance

Heat dissipation design: Reasonable heat dissipation design ensures that the inverter can still maintain a good operating temperature under high load.

Heat dissipation holes and thermal conductive materials: Heat dissipation holes and thermal conductive materials are added to the PCB design to further enhance the heat dissipation effect.

3.Technical Parameters

| Number of layers | 4 layers | Surface treatment | lead-free tin spraying |

| Board material | FR4, SY1000 | Copper thickness | high-voltage DC power supply system, inner and outer layer copper thickness 2oz |

| Board thickness | 1.6mm | Hole copper thickness | 25um |

| Minimum aperture | 0.50mm | / | / |

4.Application Areas

Solar inverter: used for various types of solar inverters, including photovoltaic power generation systems and off-grid systems.

Power conversion: suitable for power conversion needs of homes, businesses and industries.

Energy storage system: combined with energy storage equipment to achieve efficient energy management.

5.Production Process

1. Design: Use professional software for circuit design and layout to ensure the efficiency and reliability of the circuit.

2. Plate making: Make a photolithography plate according to the design file and perform preliminary processing of the PCB.

3. Etching: Remove the excess copper layer to form a circuit pattern.

4. Drilling: Drill holes according to design requirements to connect circuits between different layers.

5. Surface treatment: Anti-oxidation treatment is performed to improve welding performance.

6. Testing: Electrical testing is performed to ensure product quality and performance.

|

|

6.Summary

The four-layer solar inverter PCB is an indispensable component of solar inverters. With its excellent electrical performance and high-density design, it is widely used in various solar power generation systems. Whether it is power conversion or energy management, the four-layer solar inverter PCB can meet the needs of modern solar energy applications and ensure that users get an efficient energy utilization experience.

FAQ

Q: Do You have office in shanghai or shenzhen that i can visit?

A: We are in Shenzhen.

Q: Will you attend the fair to show your products?

A: We're planning on it

Q: How long it takes you to provide the designing options for us?

A: 3 days

Q: Electromagnetic interference problem?

A: It can be solved by rationally arranging components and adding shielding layers,

Q: there is also the problem of heat dissipation?

A: It can generally be improved by adding heat sinks or using high thermal conductivity materials.