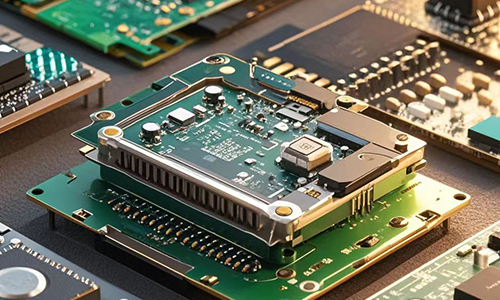

E-cigarette PCB is a PCB designed for e-cigarette devices, usually used to connect batteries, heating elements, sensors and control circuits.

Technical Specifications

| Number of layers | 2 | Minimum line width and line spacing | 0.4/0.4mm |

| Board thickness | 1.6mm | Minimum aperture | 0.3 |

| Board material | KB-6160 | Surface treatment | lead-free tin spraying |

| Copper thickness | 1/1oz | lead-free tin-spraying |

| WHY US |

||||

|

|

|

||

| Fast Delivery | High Quality | Diversified Customization | ||

| Factory | ||||

|

|

|

||

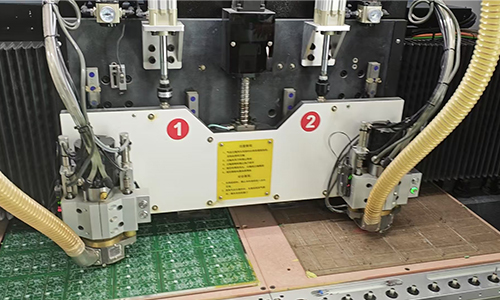

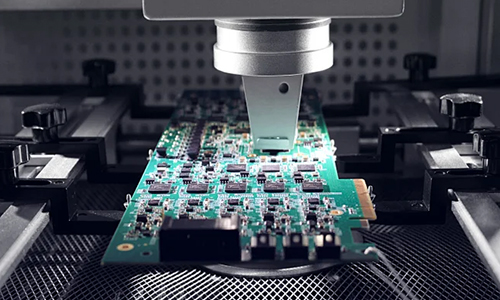

| Photoengraving Workshop | Drilling Machine | Electroplating Production Line | ||

| More Information | ||

| Strategic Partners | Application | Certificate |

FAQ

1.Q: What files are used in PCB production?

A: PCB production requires Gerber files and PCB manufacturing specifications, such as the required substrate material, finished thickness, copper layer thickness, solder mask color, and design layout requirements.

2.Q: When can I get a quotation after I provide Gerber, product process requirements?

A: Our sales staff will give you a quotation within 1 hour.

3.Q: How to solve the common overheating problems when using electronic PCB ?

A: The key is to introduce heat dissipation design and or choose high quality materials. For example: EMC, TUC, Rogers and other companies to provide the board.

4.Q: Can you manufacture HDI printed circuit board substrates?

A: We can manufacture any interconnect PCB from four-layer, one-layer to 18-layer HDI.