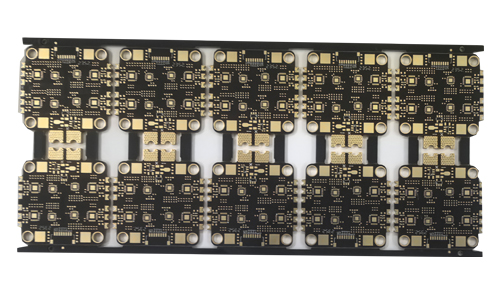

The 6-layer UAV PCB is a high-performance printed circuit board designed for UAV electronic motherboards.

6-Layer UAV-Specific Electronic PCB Product Introduction

1.Product Overview

The 6-layer UAV PCB is a high-performance printed circuit board designed for UAV electronic motherboards. It adopts a 6-layer structure to meet the needs of complex electronic systems, provide stable signal transmission and excellent electromagnetic compatibility. This PCB has become an ideal choice in the field of UAVs with its excellent performance and reliability.

2.Product Features

1. Multi-layer structure design: Adopting a 6-layer PCB design, it provides more wiring layers, effectively reduces signal interference, and improves circuit performance.

2. High reliability: Select high-quality raw materials to ensure stability and reliability during the flight of the UAV.

3. Accurate wiring: Minimum line width/line spacing design to ensure the accuracy of the circuit and high-speed transmission of signals.

4. Environmentally friendly materials: Use environmentally friendly inks to reduce the impact on the environment and meet international environmental standards.

5. Surface treatment technology: Use advanced surface treatment technology to enhance the corrosion resistance and wear resistance of PCB.

3.Technical Specifications

| Number of layers | 6 layers | Ink color | Black |

| Raw materials | High Tg halogen-free FR-4 epoxy fiberglass substrate | Minimum line width/line spacing Line width | 0.1mm, line spacing: 0.1mm |

| Thickness | 1.6mm | Is there a solder mask Yes | using a black solder mask |

| Copper thickness | 1OZ/35 microns | Surface treatment | Hot air leveling (HASL), chemical gold (ENIG) |

4.Application areas

1. General drone electronic motherboard

2. Military drones

3. Aerospace electronic equipment

4. Commercial drones

5.Production process

Precise laser drilling technology: ensure drilling accuracy and improve PCB reliability.

High density interconnect technology (HDI): achieve smaller component spacing and improve the space utilization of circuit boards.

Automated production line: improve production efficiency and consistency of product quality.

6.Summary

6-layer drone PCB has become an ideal choice for drone electronic motherboards with its excellent multi-layer structure design, high reliability, precise wiring, environmentally friendly materials and advanced surface treatment technology. It not only meets the needs of drones for high-performance circuit boards, but also ensures the quality and performance of the product through special production processes. This PCB is a reflection of technological progress in the field of drones, and provides a solid foundation for the stable operation and performance improvement of drones.

FAQ

1.Q: How far is your factory from the nearest airport?

A: About 30 kilometers

2.Q: What is your minimum order quantity?

A: One piece is enough to place an order.

3.Q: What to do if solder mask overflow affects soldering quality?

A: Solder mask overflow refers to the situation where the solder mask covers the pads or vias that should be exposed, affecting the soldering quality. To address this issue, precise window settings for the solder mask should be made during the design phase and communication with the manufacturer should be confirmed to ensure their process capabilities prevent excessive overflow.

4.Q: What to do if PCB warps or deforms during manufacturing or soldering?

A: Warping and deformation of PCBs during manufacturing or soldering are due to thermal stress, which can affect assembly and functionality. Strategies to mitigate this include selecting appropriate base materials and controlling the uniformity of heating during the process. In some cases, adding stiffeners in the design can reduce the risk of warping.