Last time we learned about the background and the origin of Bosch.

In this article, we will learn about the etching gas SF6 and the passivation gas C4F8 in Bosch technique.

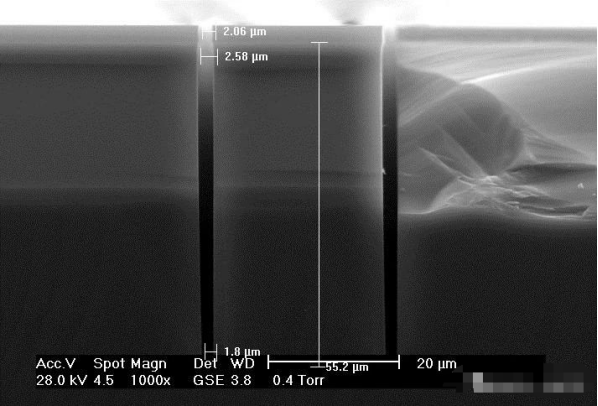

The Bosch process achieves high aspect ratio and steep sidewall etching of silicon structures by alternating etching and passivation gases. SF6 (Sulfur Hexafluoride) serves as the etching gas, which dissociates in plasma to form atomic fluorine that reacts with silicon to produce gaseous SiF4, thus achieving silicon etching.

C4F8 (Octafluorocyclobutane) acts as the passivation gas; in the plasma, its cyclic molecules break and become short-chain molecules with active ends that combine with other molecules, growing in length and attaching to silicon to form a membrane. This membrane prevents sidewall etching during the etching process.

In the next article we will learn about the process mechanism of Bosch.