Today we will continue to learn about the second method of manufacturing PCB SMT stencils: Laser Cutting.

Laser cutting is currently the most popular method for manufacturing SMT stencils. In the SMT pick-and-place processing industry, more than 95% of manufacturers, including us, use laser cutting for stencil production.

1. Principle Explanation: Laser cutting involves using a laser to cut where apertures are needed. The data can be adjusted as needed to change the size, and better process control will improve the accuracy of the apertures. The hole walls of laser-cut stencils are vertical.

2. Process Flow: Film making for PCB → Coordinate acquisition → Data file → Data processing → Laser cutting and drilling → Polishing and electro-polishing → Inspection → Tensioning the mesh → Packaging

3. Features: High precision in data production, minimal influence from objective factors; trapezoidal apertures facilitate demolding; capable of precise cutting; moderately priced.

4. Disadvantages: Cutting is done one by one, which makes the production speed relatively slow.

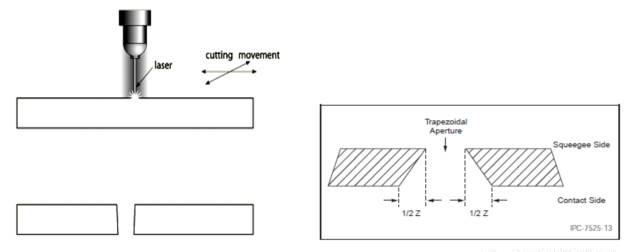

The principle of laser cutting is shown in the lower left image below. The cutting process is finely controlled by the machine and is suitable for the production of extremely small pitch apertures. Since it is directly ablated by the laser, the hole walls are straighter than those of chemically etched stencils, without a conical middle shape, which is conducive to the filling of solder paste into the stencil apertures. Moreover, because the ablation is from one side to the other, the hole walls will have a natural inclination, making the entire hole's cross-section a trapezoidal structure, as shown in the lower right image below. This bevel is roughly equivalent to half the thickness of the stencil sheet.

The trapezoidal structure is beneficial for the release of solder paste, and for small hole pads, it can achieve a better "brick" or "coin" shape. This characteristic is suitable for the assembly of fine pitch or micro components. Therefore, for precision component SMT assembly, laser stencils are generally recommended.

In the next article, we will introduce the electroforming method in PCB SMT stencil.