Today, we will continue to explore the three methods of manufacturing PCB SMT stencils: Chemical Etching (Chemical Etching Stencil), Laser Cutting (Laser Cutting Stencil), and Electroforming (Electroformed Stencil).

Let's start form chemical etching:

1. Principle Explanation: Chemical etching refers to the use of corrosive chemical solutions to remove the metal at the positions that need to be holed in the stainless steel sheet, creating apertures that correspond to the PCB pads and meeting the requirements of the SMT pick-and-place processing production stencil.

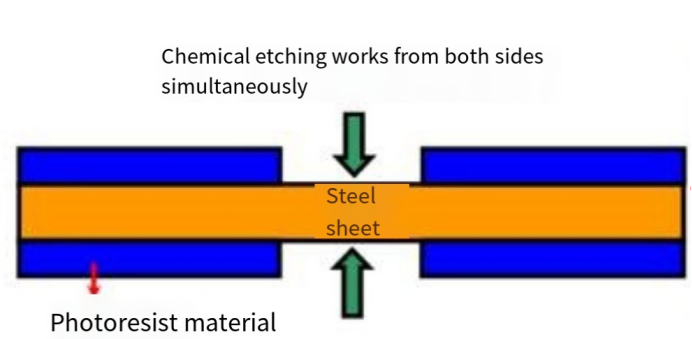

2. Process Flow: Cut the stainless steel sheet to the appropriate size → Clean → Apply photoresist material → UV exposure → Develop and dry → Chemical etching → Strip the photoresist material → Clean and dry → Inspect → Tension the mesh → Package.

3. Features: One-time forming, faster speed; low cost.

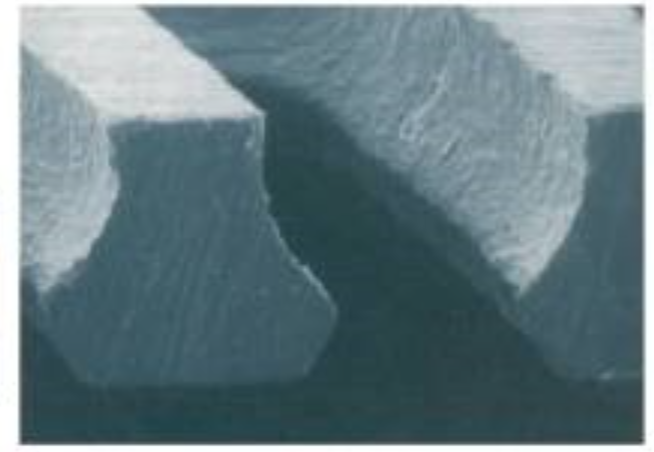

4. Disadvantages: Prone to forming hourglass shapes (inadequate etching) or increasing aperture sizes (over-etching); significantly affected by objective factors (experience, chemicals, film), many production steps, large cumulative errors, not suitable for fine pitch stencil production; the production process is polluting and not environmentally friendly, and has gradually been phased out.

Since chemical etching works from both sides of the steel sheet to remove the metal parts (as shown in the lower left image), the hole walls are smooth and vertical. However, it may not completely remove the metal at the center of the sheet thickness, forming a conical shape, and its cross-section appears in a funnel shape (as shown in the upper image). This structure is not conducive to the release of solder paste. Therefore, etched stencils are generally not recommended for precision component assembly. Components with pin pitch less than 0.5mm or smaller than 0402 size are not advised to use etched stencils. Of course, for the assembly of some large components or components with larger pitch values, etched stencils have a significant cost advantage and can also meet the production quality requirements of many customers and SMT pick-and-place processing factories.

In the next article, we will introduce the laser cutting method in PCB SMT stencil.