In the PCB manufacturing process, the creation of tapered holes is a critical step, which involves three main stages: the fabrication of straight holes, the formation of tapered holes, and the rounding of hole corners.

Today, we will first explore the process of making straight holes. Straight holes, also known as Plated Through Holes (PTH), are the most common type of via hole in PCBs.

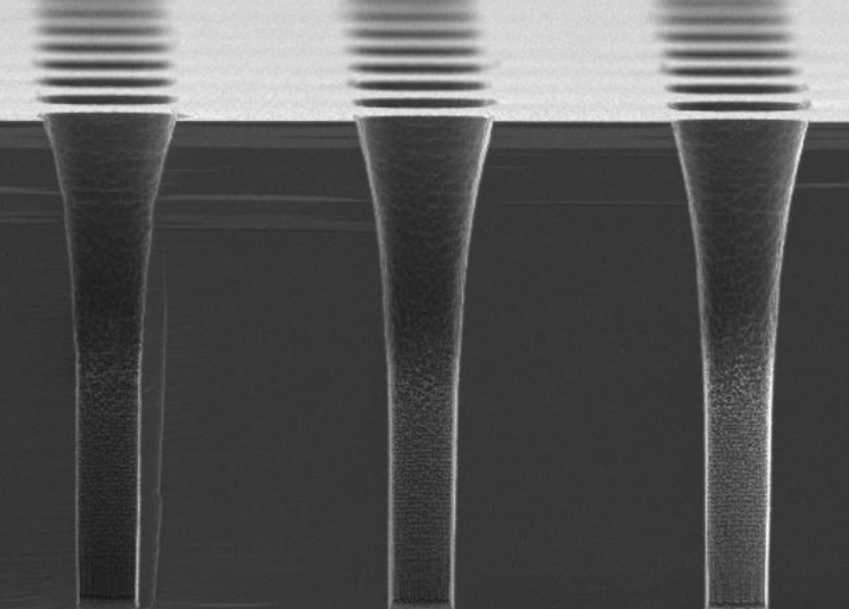

The first step in creating straight holes is drilling, which is done using a drilling machine to make holes of the required size in the PCB board. Subsequently, the hole walls are treated with a chemical or electroplating copper layer to increase the conductivity of the hole walls and prepare for subsequent plating processes. This process ensures the verticality and precision of the holes, laying a solid foundation for the manufacturing of tapered holes.

In the next article, we will delve into how to manufacture tapered holes.