Let's continue to talk about the next step: Bottom Passivation Layer Etching.

Bottom Passivation Layer Etching:

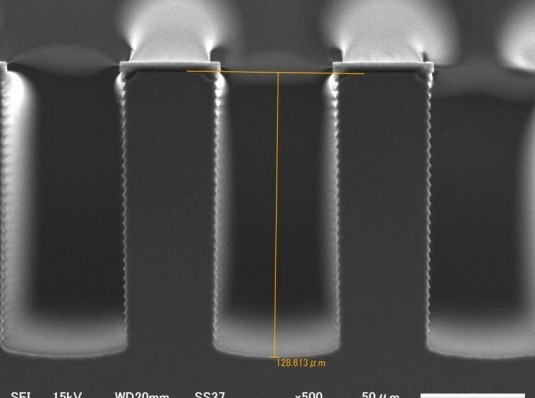

After the silicon etching is completed, both the sidewalls and the bottom form a passivation layer. Our goal is to retain the sidewall passivation layer to protect it from further etching while removing the bottom passivation layer to continue etching deeper. To achieve this, SF6 gas is introduced, which attacks and removes the bottom passivation layer. Once the bottom passivation layer is removed, SF6 gas continues to etch the silicon. This process continues in a cycle to achieve deeper etching.

In the Bosch process, by adjusting parameters such as gas flow rate, pressure, etching time, and passivation time, the bottom passivation layer can be effectively removed while retaining the sidewall passivation layer, thus achieving high aspect ratio structures.

Furthermore, when using the Bosch process for dry etching, ICP-RIE or DRIE machines are required. These machines provide high etching rates, high selectivity, and low damage processing while maintaining excellent profile control.

In future articles, we will introduce how to use these two types of machines for the Bosch process operations.