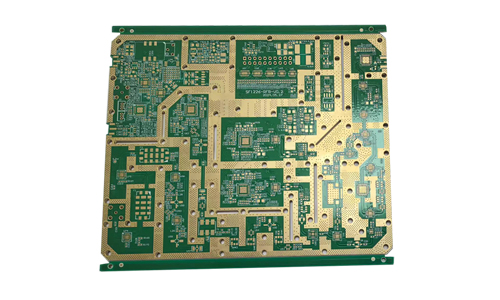

The Six-Layer High Frequency PCB With Rogers is designed for high-frequency and high-speed applications.

Six-Layer High Frequency PCB With Rogers Product Introduction

1.Product Overview

The Six-Layer High Frequency PCB With Rogers is designed for high-frequency and high-speed applications. It uses Rogers material as the base material and combines the advantages of other materials to have excellent electrical and mechanical properties. This type of circuit board is widely used in communications, radar, aerospace, medical equipment and other fields.

2.Product Features

1.Excellent dielectric properties:

2.Rogers material has low dielectric constant (Dk) and low dielectric loss (Df), ensuring high efficiency and stability of signal transmission, suitable for high-frequency applications.

3.Good thermal stability:

4.The PCB can still maintain excellent electrical performance in a high-temperature environment, suitable for high-power and high-temperature working environments.

5.Multi-layer structure design:

6.Provides higher design flexibility, supports complex circuit layout and signal integrity, and is suitable for a variety of application requirements.

7.Mixed-pressure technology:

8.Combining the advantages of different materials, mixed-pressure technology can reduce production costs and improve production efficiency while ensuring signal quality.

9.Chemical resistance:

10.Rogers materials have excellent chemical resistance and are suitable for use in harsh environments.

11.Lightweight design:

12.Compared with traditional materials, the lightweight characteristics of Rogers materials help reduce the overall weight of the device and improve portability.

3.Technical Specifications

| Number of layers | 6 layers | Ink color | green oil white text |

| Material | Rogers + FR-4, S1000 | Minimum line width/line spacing | 0.1mm/0.1mm |

| Thickness | 2.0mm | Is there solder mask | yes |

| Copper thickness | inner 0.5 outer layer 1OZ | Surface treatment | immersion gold |

4.Application Areas

Communication equipment: such as base stations, antennas, RF modules, etc.

Aerospace: electronic equipment for aircraft and satellites.

Radar system: suitable for military and civilian radar systems.

Medical equipment: such as imaging equipment, monitoring equipment, etc.

Automotive electronics: automotive electronic systems for high-frequency signal transmission.

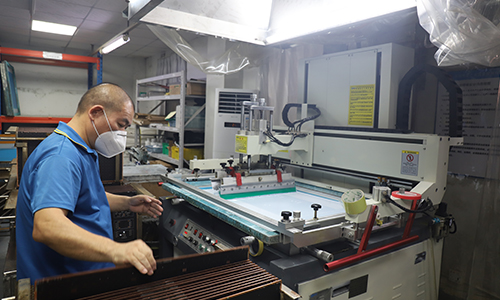

5.Production Process

Precision etching: ensure the accuracy of circuit graphics to meet the requirements of high-density interconnection (HDI).

Multi-layer stacking: Combine different layers of materials through high temperature and high pressure process to ensure electrical performance and mechanical strength.

Surface treatment: Different surface treatment methods such as HASL, ENIG, etc. can be provided according to customer needs to ensure welding reliability.

|

|

6.Conclusion

The Six-Layer High Frequency PCB With Rogers has become an indispensable and important part of modern electronic devices with its excellent performance and wide application prospects. Whether in signal transmission, thermal management or durability, it has shown significant advantages and is an ideal choice for high-end electronic product design.

FAQ:

Q: How far is your factory from the nearest airport?

A: About 30 kilometers

Q: What is your minimum order quantity?

A: One piece is enough to place an order.

Q: What problems can impedance mismatch in HDI high-frequencyPCB cause?

A: The impedance of transmission lines on the PCB not matching the output impedance of the signal source or driver can lead to signal reflection, crosstalk, and signal integrity issues.

Q: Is there a coating layer between the copper foil and dielectric in RO3003 and RO3003G2 materials?

A: Rogers Corporation's RO3003 and RO3003G2 materials do not have a coating layer between the copper foil and dielectric. The dielectric layer and copper foil are directly laminated at high temperatures, which can be observed in cross-sections.

Q: How long does it generally take to deliver HDI high-frequency PCB?

A: We have raw material inventory (such as RO4350B, RO4003C, etc.), and our fastest delivery time can be 3-5 days.