Wireless gaming keyboard PCB (printed circuit board) is a core component designed for wireless gaming keyboards, aiming to provide efficient, stable wireless connection and excellent user experience.

PCB For Wireless Game Keyboard Product Introduction

|

|

1.Product Overview

Wireless gaming keyboard PCB (printed circuit board) is a core component designed for wireless gaming keyboards, aiming to provide efficient, stable wireless connection and excellent user experience. They are widely used in multiple fields such as games, office and entertainment.

2.Product Features

Wireless communication technology

Support wireless communication protocols such as Bluetooth and 2.4GHz to ensure low latency and stable connection.

Possess strong anti-interference ability to ensure normal use in complex environments.

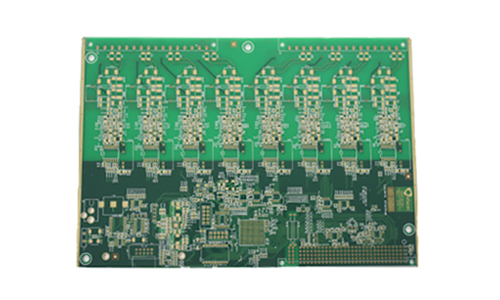

High-performance circuit design

Adopt high-quality electronic components to ensure the stability and reliability of signal transmission.

Low power consumption design to extend battery life and suitable for long-term gaming.

Multi-function integration

Integrate multiple functions such as RGB backlight, macro programming, volume control, etc. to enhance user experience.

Support hot-swap function to facilitate users to replace keycaps and switches.

Compact layout

Adopt compact PCB design to save space and adapt to keyboards of different sizes.

Design optimization to reduce signal interference and improve overall performance.

3.Technical Specifications

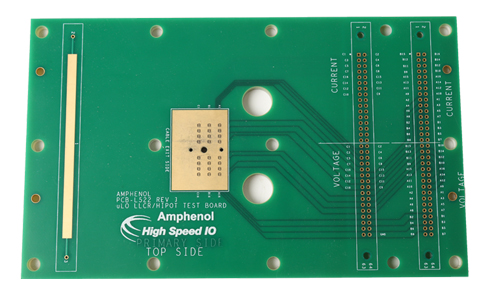

| Number of layers | 2 layers | Ink color | green oil with white characters |

| Material | FR-4 S1141 | Minimum line width/line spacing | 0.1mm/0.1mm |

| Thickness | 3.0mm | Features | controlled depth sinking 2.0MM |

| Copper thickness | 1oz inner layer, 1oz outer layer | Surface treatment | immersion gold |

4.Application Areas

Gaming keyboard

Designed for gamers, providing fast response and comfortable typing experience.

Office keyboard

Suitable for long-term use, reducing fatigue and improving work efficiency.

Multimedia control

Can be used for multimedia controllers to facilitate users to adjust volume and control playback.

Manufacturing process

Material selection

Common materials include FR-4 and high-frequency materials to ensure the performance and durability of the circuit board.

Printing process

Adopt advanced screen printing and photolithography technology to ensure the accuracy of the line.

Assembly process

Adopt surface mount (SMT) technology to ensure the firmness and reliability of components.

5.Quality Control

Strict testing process

Including functional testing, wireless signal testing, withstand voltage testing, etc., to ensure the quality of each PCB.

Compliance with international standards

Passed ISO9001 and other quality management system certifications to ensure that the product meets international standards.

|

|

6.Conclusion

The wireless gaming keyboard PCB circuit board is the core component of the modern wireless gaming keyboard. With its high performance and multi-functional design, it provides users with an excellent use experience. Choosing the right manufacturer and material can ensure the stability and reliability of the wireless gaming keyboard and meet the needs of different users.

FAQ

Q: How many employees do you have in your factory?

A: More than 500.

Q: Are the materials you use environmentally friendly?

A: The materials we use are in accordance with ROHS standard and IPC-4101 standard.

Q: What problems can be caused by inaccurate PCB design in mobile phones?

A: If the circuit design lacks a rational layout, it may lead to signal interference and unstable transmission, thereby affecting the performance of the entire phone. Therefore, we need to fully consider the position of each component and the rationality of the wiring during the PCB design phase.

Q: Can a lack of strict control during the production process lead to many problems?

A: In the production process, issues such as uneven plating thickness and inaccurate milling can negatively impact the performance of PCB. Therefore, strict control of the production process is key to ensuring quality.