Today we will learn about the process of Bosch technique, The Bosch process is achieved through a cycle of three steps: silicon etching, sidewall and bottom passivation, and bottom passivation layer etching. These three steps form a cycle, and deep silicon etching may require multiple such cycles. First, Let’s start from silicon etching.

silicon etching

During the silicon etching step, only the silicon at the bottom is etched, while the sidewalls are protected by the passivation layer previously deposited. SF6 gas is introduced and dissociates in the plasma to form highly reactive fluorine atoms (F).

SF6-->SF4+F2-->SF2+2F2-->F+...

Which react with the silicon surface to produce silicon tetrafluoride (SiF4), a volatile compound that is easily evacuated from the chamber.

Si+4F-->SiF4

This process ensures that silicon etching only occurs at the bottom, while the sidewalls remain steep, thus achieving high aspect ratio structures.

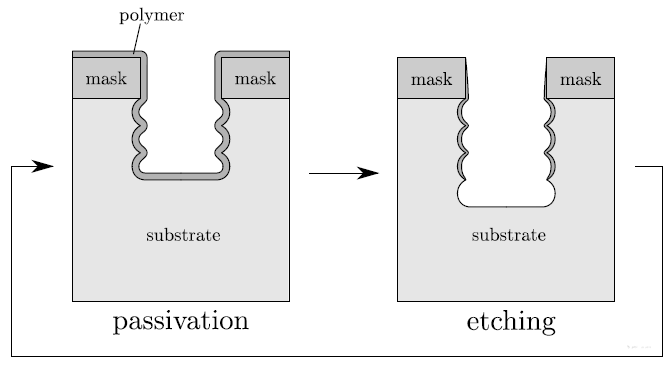

Next, we will learn about the second step: sidewall and bottom passivation.