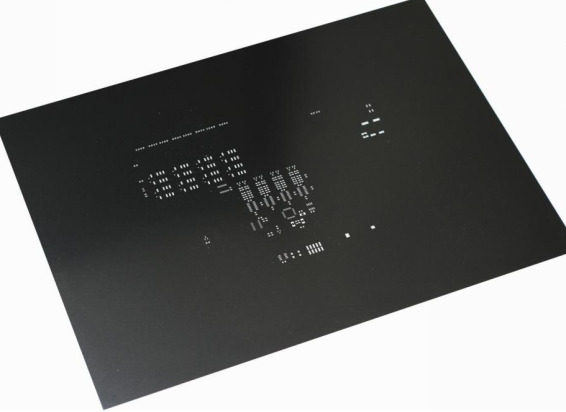

Today, let's explore how to test SMT stencils.

The quality inspection of SMT stencil templates is mainly divided into the following four steps:

(1) Inspect whether the frame size meets the requirements and the quality of the mesh tensioning— the tighter the mesh, the better the printing quality;

(2) Check the exterior quality of the template apertures for any obvious defects, such as the shape of the apertures, and whether there are any abnormalities between the high-density or narrow-pitch pins;

(3) Use a magnifying glass or microscope to inspect whether the bell mouth of the pad apertures is facing down, and whether the inner walls around the apertures are smooth and free of burrs, with a focus on inspecting the processing quality of the apertures for narrow-pitch IC pins;

(4) Place the printed circuit board of the product on the bottom side of the template, align the holes of the template with the pad patterns on the printed circuit board, and check whether the patterns are fully aligned, and whether there are any extra holes (unnecessary apertures) or missing holes (omitted apertures).

That concludes all the information about PCB SMT stencils. If you are also interested in customizing a PCBA similar to the one mentioned in the news before, please feel free to contact our sales personnel to place an order.