Today we will continue to learn about the last method of manufacturing PCB SMT stencils: Hybrid process.

Hybrid process technique, also known as the step stencil manufacturing process, involves creating a stencil with two or more thicknesses on a single steel sheet, which is different from the standard stencil that typically has only one thickness. The purpose of this process is to meet the varying requirements for solder volume among different components on a board. The manufacturing process for a step stencil combines one or two of the previously mentioned stencil processing techniques to create a single stencil. Generally, many SMT assembly factories will first use the chemical etching method to obtain the required thickness of the steel sheet, and then use laser cutting to complete the processing of the holes.

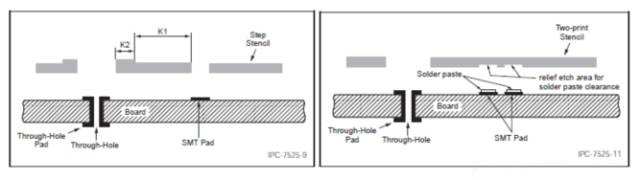

Step stencils come in two types: Step-up and Step-down. The manufacturing process for both types is essentially the same, with the decision between Up and Down depending on whether the local area in question requires an increase or decrease in thickness. If the assembly requirements for small-pitch components on a large board (such as CSPs on a large board) necessitate a greater amount of solder for the majority of components, while a reduced amount of solder is needed for small-pitch CSP or QFP components to prevent short circuits, or if a void is required, a Step-down stencil can be used. This involves thinning the steel sheet at the positions of small-pitch components, making the thickness in these areas less than in other areas. Conversely, for a few large-pin components on a precision board, the overall thinness of the steel sheet may result in an insufficient amount of solder paste deposited on the pads, or for through-hole reflow processes, a larger amount of solder paste may sometimes be needed in the through-holes to meet the solder filling requirements inside the holes. In such cases, a Step-up stencil is required, which increases the thickness of the steel sheet at the positions of large pads or through-holes to increase the amount of solder paste deposited. In actual production, the choice between the two types of stencils depends on the types and distribution of components on the board.

Next we will introduce the testing standards of SMT stencil.