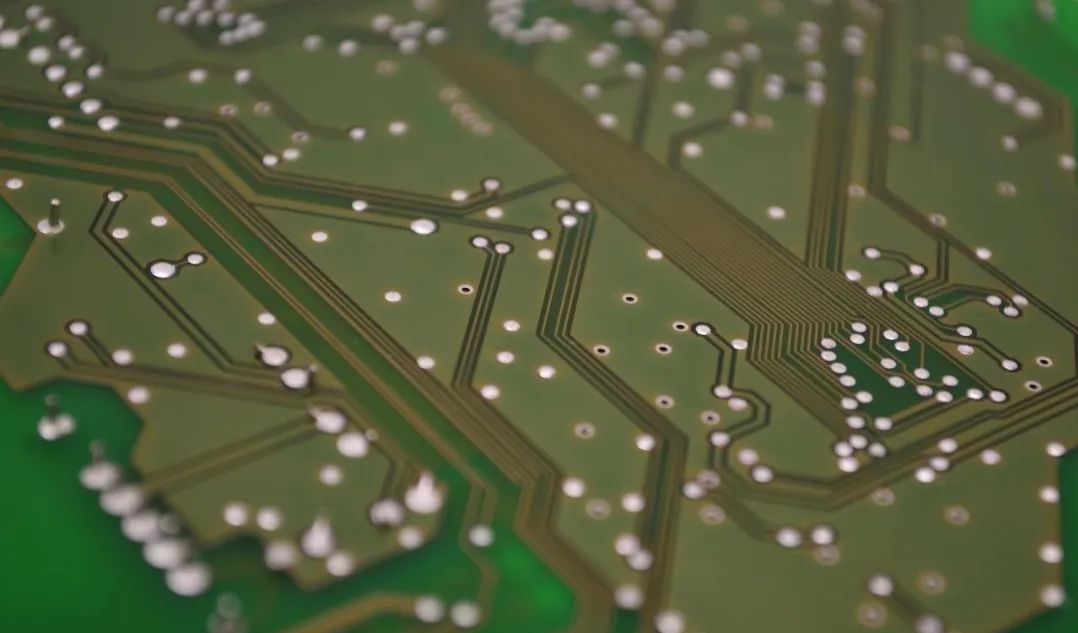

Continuing our discussion on PCB electrical safety clearances, let's introduce two more types: the safety clearance between pads and the safety clearance between copper foil and the board edge.

1. The clearance between pads:

Based on the manufacturing capabilities of PCB manufacturers, it is recommended that the clearance between pads should not be less than 0.2mm,

2. The clearance between copper foil and the board edge:

The clearance between powered copper foil and the PCB board edge should ideally not be less than 0.3mm. If it is a large area of copper pouring, it usually also requires an inner shrinkage distance from the board edge, generally set to 20mil.

In general, for mechanical considerations of the circuit board, or to avoid issues such as edge curling or electrical short circuits that may be caused by copper foil exposure at the board edge, engineers often shrink the large copper pouring blocks relative to the board edge by 20mil, rather than extending the copper foil all the way to the edge. There are various methods for this copper foil shrinkage treatment. For example, drawing a keepout layer on the board edge and then setting the distance between copper pouring and keepout