Next, let's introduce the third type of dry etching equipment: IBE, which stands for Ion Beam Etching system.

In this process, a concentrated ion beam directly hits the surface of the material to be etched. The physical impact of ions on the material surface causes the atoms or molecules on the surface to be stripped off, thus achieving etching.

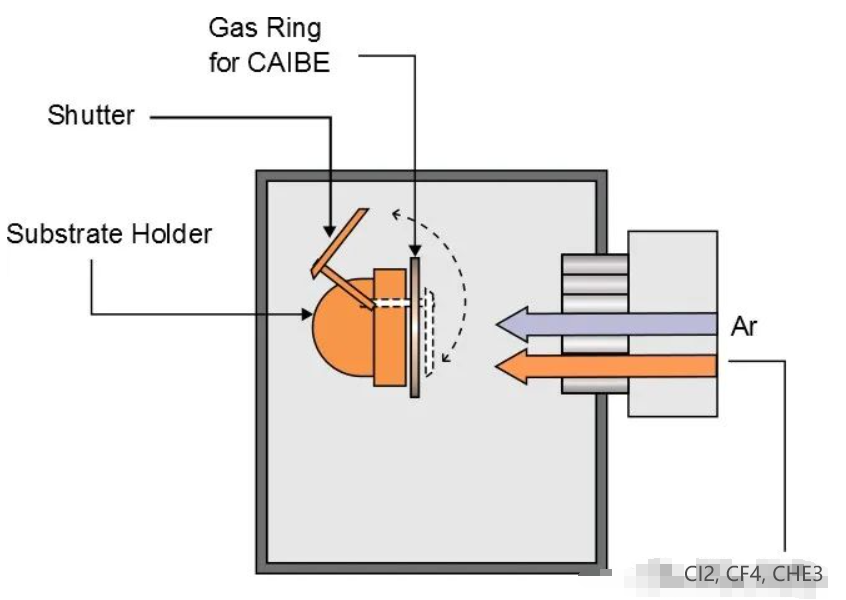

IBE is a physical dry processing technology that uses a high-energy argon ion beam with an energy of about 1 to 3keV to irradiate the material surface. The energy of the ion beam causes it to collide and remove surface materials. The etching process is anisotropic in the case of vertical or oblique incident ion beams, making IBE particularly suitable for applications requiring high directional etching.

All the above content introduces the three commonly used dry etching machines. Dry etching is an important micro-nano processing technology, with the advantages of high precision, strong controllability, and wide applicability of materials, which has a profound impact on modern technology and industry.

Our factory also has the relevant technology, thus being able to create high-end PCB products for customers.

Dry etching technology achieves high precision, high anisotropy, and high selectivity through physical, chemical, and physicochemical combined mechanisms.