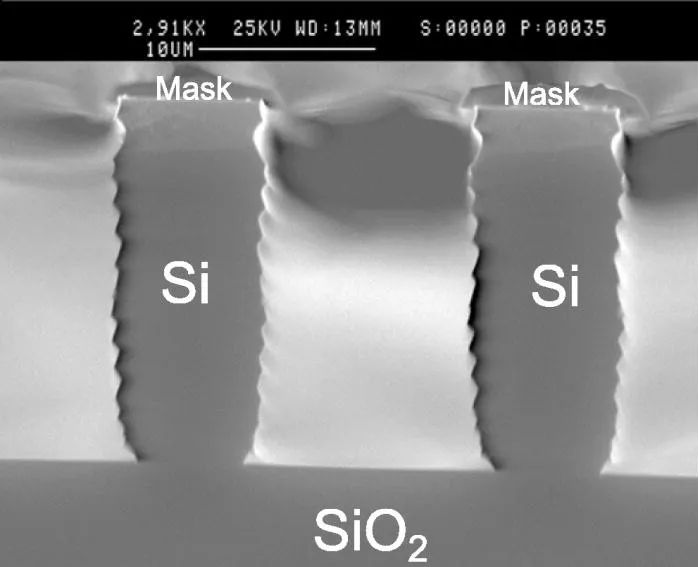

Dry etching is a method that uses gases or plasma to etch materials. It is one of the key steps in microelectronic manufacturing, primarily used to form small structures on semiconductor chips. This technique is highly valued for its precision and anisotropy, capable of fine processing at the nanoscale and creating high directional patterns perpendicular to the substrate, which is crucial for the fabrication of three-dimensional structures, such as deep holes and trenches in microelectronic devices.

Plasma

Plasma is the fourth state of matter, distinct from solid, liquid, and gaseous states. It is an ionized gas composed of equal parts ions and electrons, with a net charge of zero. The formation of plasma typically requires high temperatures or strong electric fields, which strip electrons from atoms or molecules. Plasma has high electrical conductivity and reactivity, as well as responsiveness to electromagnetic fields, making it instrumental in dry etching.

Characteristics of Dry Etching

The characteristic of dry etching is its ability to provide excellent fine processing capabilities and anisotropy. This technique can achieve very precise etching control, suitable for fine processing at the nanoscale. It enables etching perpendicular to the substrate, creating high directional patterns, which is particularly useful for manufacturing three-dimensional structures, such as deep holes and trenches in microelectronic devices.

In dry etching systems, specific types of gases are introduced into the etching chamber and ionized by electromagnetic fields to generate plasma. The ions or reactive molecules in this plasma will strike the surface of the material to be etched, causing physical or chemical reactions that remove the material. Dry etching requires the use of complex etching equipment, such as plasma etchers, which are costly to purchase and maintain, thus making the cost of dry etching relatively high.

In the next article, we will introduce the types of dry etching equipment, including Electron Cyclotron Resonance (ECR) and Inductively Coupled Plasma (ICP).