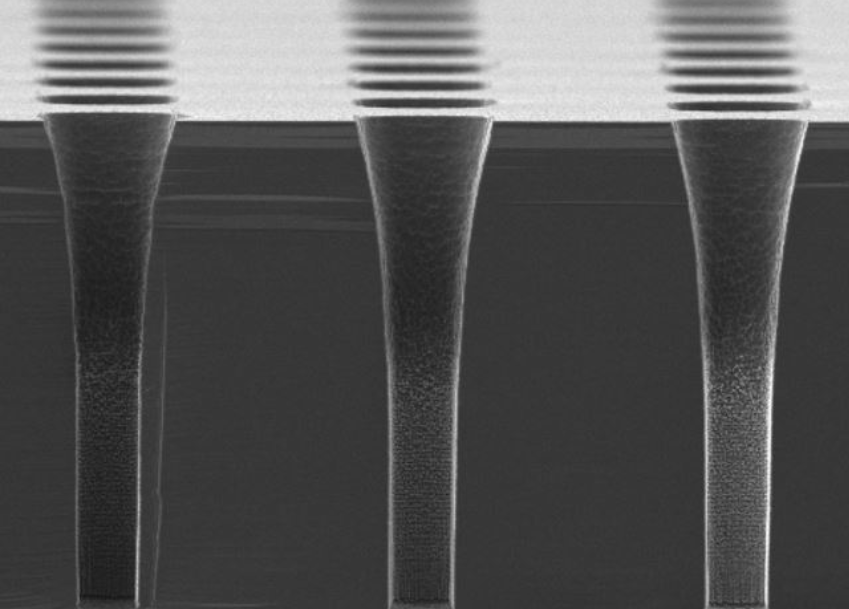

Lastly, we discuss how to round the tapered holes.

This step involves removing the photoresist covering the surface of the wafer, exposing the entire bare wafer to the plasma. This step uses SF6 and O2, differing from before by not including Ar gas, thus the physical bombardment effect is weaker, and it is primarily a chemical action, achieving isotropic etching to smooth sharp corners and rough sidewalls.

This process is crucial for ensuring the quality and performance of the tapered holes. The above are all the steps in manufacturing tapered holes.

If you are interested in our sharing, please look forward to our subsequent knowledge explanations, or contact our customer service to learn more about Sanxis.