Last time we mentioned the “flip chip” in the chip packaging technology table, then what is the flip chip technology? So let's learn that in today’s new.

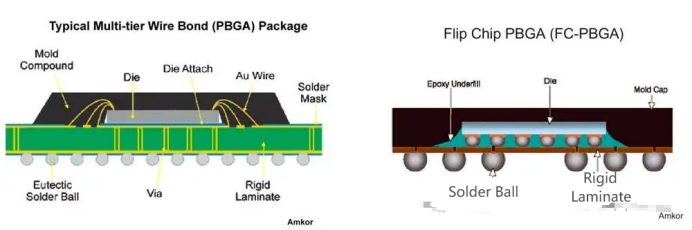

As shown in the cover picture,

The one on the left is the traditional wire bonding method, where the chip is electrically connected to the pads on the packaging substrate through Au Wire. The front side of the chip is facing up.

The one on the right is the flip chip, where the chip is directly electrically connected to the pads on the packaging substrate through Bumps, with the front side of the chip facing down, flipped over, hence the name flip chip.

What are the advantages of flip chip bonding over wire bonding?

1. Wire bonding requires long bonding wires, while flip chips connect directly to the substrate through bumps, resulting in shorter signal paths that can effectively reduce signal delay and parasitic inductance.

2. Heat is more easily conducted to the substrate as the chip is directly connected to it via bumps, enhancing thermal performance.

3. Flip chips have a higher I/O pin density, saving space and making them suitable for high-performance, high-density applications.

So we learned that flip chip technology can be considered as a semi-advanced packaging technique, serving as a transitional product between traditional and advanced packaging. Compared to today's 2.5D/3D IC packaging, flip chip is still a 2D packaging and cannot be vertically stacked. However, it has significant advantages over wire bonding .