We all know that during the production process of PCB circuit boards, it is inevitable to have electrical defects such as short circuits, open circuits, and leakage due to external factors. Therefore, to ensure product quality, the circuit boards must undergo strict testing before leaving the factory.

The main methods of PCB testing are flying probe testing and test fixture testing.

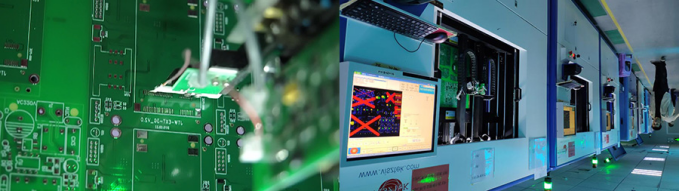

1. Flying Probe Testing

Flying probe testing utilizes 4 to 8 probes to conduct high-voltage insulation and low-resistance continuity tests on the circuit board, checking for open and short circuits without the need for specialized test fixtures. This method involves directly mounting the PCB onto the flying probe tester and then running the test program to perform the tests. The advantage of flying probe testing is that its testing method and operational流程 are extremely convenient, saving on testing costs, eliminating the time required to produce test fixtures, and increasing the efficiency of delivery, making it suitable for the production of small batches of PCBs.

2.Test Fixture Testing

Test fixtures are specialized test jigs made specifically for continuity testing in production. The cost of making test fixtures is relatively high, but they offer high testing efficiency, and there is no charge for reorders, which also saves costs for the customer.

The two testing methods are different, and so are the machines and equipment used. The interior of a PCB test fixture is densely packed with wires connected to probes. Compared to flying probe testing, it essentially prepares all the probes corresponding to the points that need to be tested on the circuit board at once. During testing, simply press the top and bottom ends together to test the entire board for good or bad.