Today, let's learn about the various types of holes found on HDI PCBs.

There are numerous types of holes used in printed circuit boards, such as blind via, buried via, through-holes, as well as back drilling holes, microvia, mechanical holes, plunge holes, misplaced holes, stacked holes, first-tier via, second-tier via, third-tier via, any-tier via, guard via, slot holes, counterbore holes, PTH (Plasma Through-Hole) holes, and NPTH (Non-Plasma Through-Hole) holes, among others. I will introduce them one by one.

1. Drill hole

Drill holes, also known as large holes, are holes processed using mechanical methods such as drilling, grinding, boring, routing, and reaming. The smaller the hole diameter and the thicker the board, the greater the difficulty in processing. The smallest mechanical hole diameter currently is 0.15mm, which is also the most commonly used type of hole on circuit boards.

2. Laser via

Laser via, also known as micro via or laser-drilled holes, are a type of hole created using a laser beam. Due to the fixed energy of the laser, if the copper foil is too thick, the laser will not be able to penetrate it in one go and will require multiple attempts; if the copper foil is too thin, the laser will go through it, hence the copper foil used for laser via is typically 1/3 oz, which allows the laser to penetrate it just right.

The smallest laser via diameter currently used in PCB design is 0.075mm, and the use of laser via significantly increases the production cost of the circuit board. Additionally, their stability is inferior to that of mechanical holes, which is why many industries seldom utilize laser via .

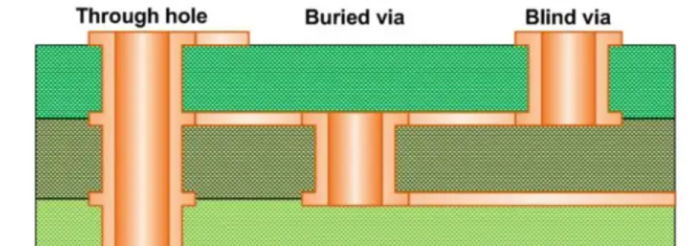

3. Through hole

Through-holes, are holes that penetrate the entire PCB board, from the top layer to the bottom layer, and are used to insert and connect components. Through-holes are primarily used to insert pins or connectors through the holes to provide a stable electrical connection and to increase mechanical strength. Through-holes are suitable for applications that require high strength and reliability, such as industrial equipment, automotive electronics, etc. Through-holes are generally mechanical holes, but any order of through-holes use laser holes.

Currently, the smallest diameter of mechanical holes is 0.15mm, which is also one of the most widely used types of holes on circuit boards. However, the smallest laser hole diameter used in PCB design is 0.075mm. The use of laser holes significantly increases the production cost of the circuit board, and their stability is inferior to that of mechanical holes, which is why many industries seldom utilize laser holes.

More kinds of holes will be shown in the next new.