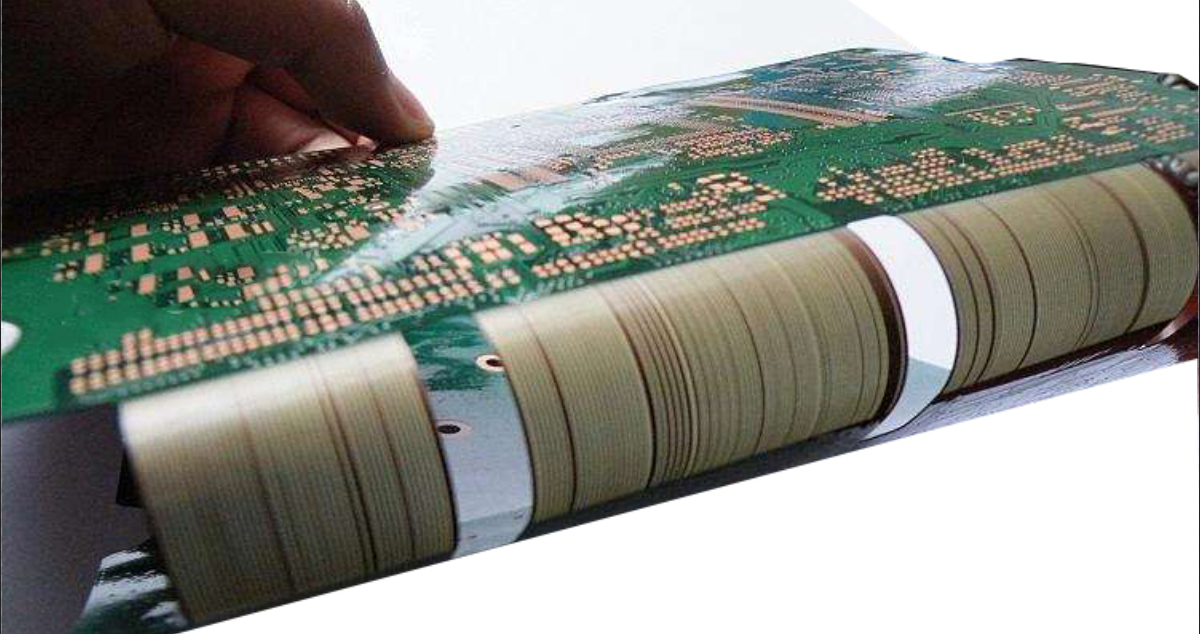

Rigid-Flex PCB, also known as rigid-flex printed circuit boards, are high-tech products that combine the stability of rigid boards with the flexibility of flexible circuits. These PCB typically consist of multiple layers of rigid boards with flexible circuit layers embedded within.

Although rigid-flex PCB may be more expensive than traditional rigid PCB due to their superior performance and adaptability, their customizability and flexibility make them a preferred choice in many high-end fields, such as military, aerospace, and medical industries. These applications require PCB with high durability to folding and elasticity to accommodate complex electronic component assembly, and their compact and flexible design is also ideal for lightweight and space-constrained electronic products.

To strike a balance between cost and performance, cost-saving measures can be taken. For instance, the number of circuit layers, materials used, and design processes can be tailored to the application requirements. With these customization options, it is possible to optimize the cost-effectiveness while maintaining the performance of rigid-flex PCB.

In the following content, we will delve into the cost components of rigid-flex PCB, including materials, manufacturing processes, design complexity, and more aspects.