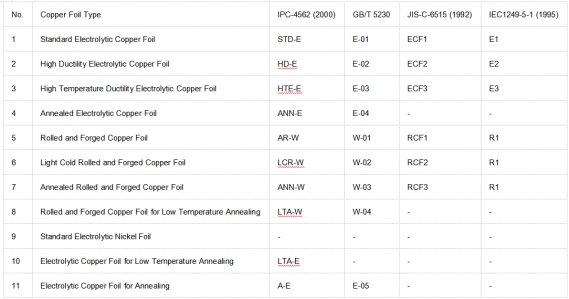

Now, let’s learn about the different types and abbreviation of copper foil:

① STD: Standard Electrodeposited Copper Foil is the most commonly used type of copper foil in PCB manufacturing, characterized by moderate roughness and good electrical properties.

② HTE: High Temperature Elongation Copper Foil, also known as HD Copper Foil (High Ductility Copper Foil), maintains excellent elongation even at high temperatures (180°C), making it suitable for PCB products that require high-temperature processing.

③ RTF: Reverse Treated Foil, also known as Reverse Copper Foil, undergoes roughening treatment on the shiny side of the copper foil to improve adhesion to insulating materials and enhance the structural stability of PCBs.

④ DST: Double Sided Treated Copper Foil undergoes roughening treatment on both the shiny and rough sides of the copper foil, eliminating the need for copper surface treatment and browning before lamination, thus reducing costs.

⑤ LP: Low Profile Copper Foil has fine crystallization without columnar crystals, which is beneficial for signal transmission and is suitable for high-frequency, high-speed PCBs.

⑥ VLP: Very Low Profile Copper Foil has an even lower profile, suitable for occasions with higher requirements for signal transmission.

⑦ HVLP: High Frequency Very Low Profile Copper Foil is specifically designed for high-frequency, high-speed circuits and has lower signal transmission loss.

⑧ UTF: Ultra Thin Copper Foil has a thickness of less than 9 microns and is used for manufacturing printed circuit boards with fine circuits.

⑨ RCC: Resin Coated Copper Foil is coated with a layer or two of a specially formulated resin adhesive on the roughened side of the copper foil. It is used in the manufacturing process of laminated multilayer boards, replacing traditional prepreg and copper foil.