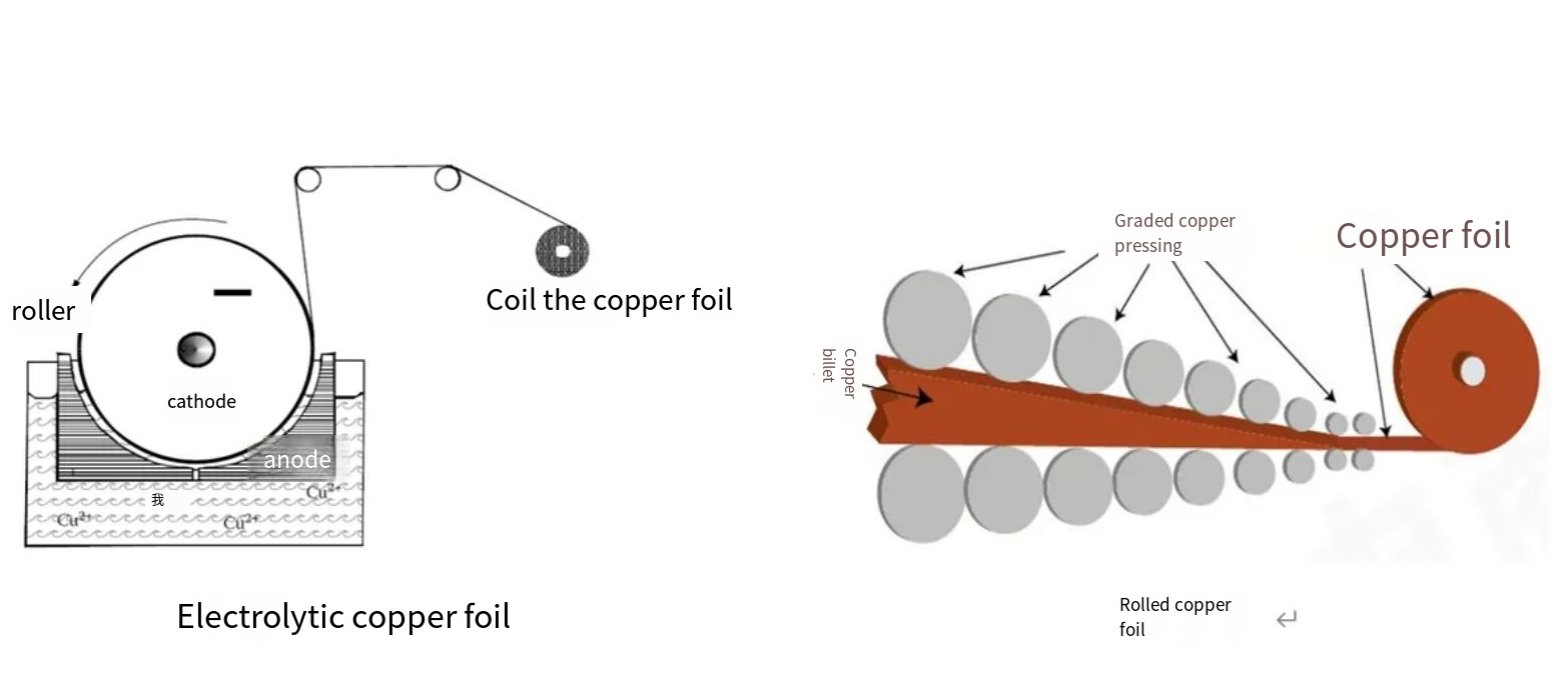

In the production and manufacturing of PCB copper foil, "electrodeposited copper foil" and "rolled copper foil" are two main copper foil production processes, each with its own characteristics and applications. In addition, you could see the two production processes more clearly in the schematic of the cover.

Electrodeposited Copper Foil:

Electrodeposited copper foil is produced through electrochemical principles, where copper material is dissolved to form copper sulfate electrolyte solution, and then the foil is made by electro-deposition in special electrolytic equipment with direct current electricity. This type of copper foil has a low production cost and relatively low technical barriers, hence it is widely used, especially in copper clad laminate PCB and lithium battery related fields. The internal structure of electrolytic copper foil is a vertical needle-like crystal structure, and different performance copper foil products can be obtained by controlling different electrolytic deposition conditions.

Rolled Copper Foil:

Rolled copper foil is made using the principle of plastic processing, through repeated rolling and annealing of high-precision copper strips. Its internal structure is a flaky crystal organization, and it has better ductility. The production process of rolled copper foil is complex and costly, but it has better physical properties, such as higher copper purity, strength, toughness, and ductility. Due to its greater resistance to folding and higher elasticity coefficient than electrolytic copper foil, rolled copper foil is commonly used in flexible copper-clad laminates (FCCL) and high-frequency circuit boards.