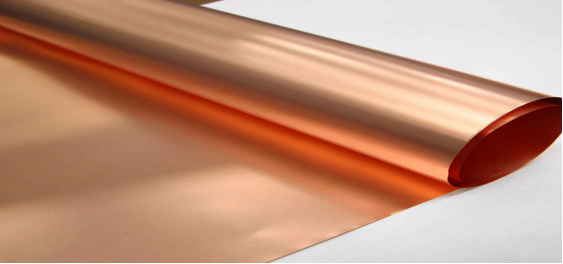

Today we are going to introduce the secret of the copper foil on PCB.

First let’s learn about the background and history of copper foil:

Copper foil is an indispensable material in the manufacturing of PCB, serving not only to conduct electricity and signals but also playing a crucial role in circuit design. In PCB, copper foil can act as a reference plane to help control the impedance of transmission lines, which is vital for high-speed signal transmission. Additionally, copper foil can serve as a shielding layer to suppress electromagnetic interference (EMI), protecting circuits from external noise.

During the PCB manufacturing process, the peel strength and etching performance of copper foil have a direct impact on the quality and reliability of PCB manufacturing. Peel strength refers to the force required to detach the copper foil from the substrate, while etching performance relates to the dissolution rate and uniformity of the copper foil during the chemical etching process.

The history of the copper foil industry dates back to 1937 when Anaconda Company in New Jersey, USA, began producing copper foil for the construction industry. By the 1970s, Japanese copper foil enterprises rapidly developed, almost monopolizing the global market and becoming the world's largest producer of copper foil, followed by Taiwan. In 1955, Yates Company in the United States started specializing in the production of copper foil for PCB. In the early 1960s, China also began producing copper foil and has gradually formed a relatively complete industrial chain. However, the technology for ultra-thin copper foil is still mainly controlled by foreign countries, especially Japan.

In the next article, we will learn about the out look difference between the matte copper foil and the shiny copper foil.