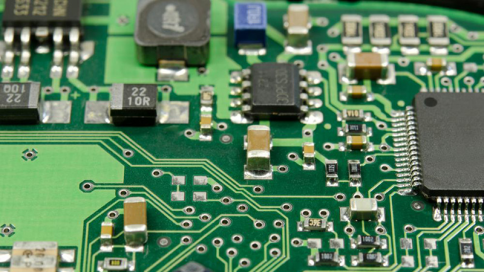

After installing electronic components on a PCB, you may need to remove them from the PCB due to reasons such as component incompatibility or damage. However, for most people, removing electronic components is not an easy task. Today, let's learn how to remove electronic components.

Let's start with single-sided PCB:

To remove components from a single-sided printed circuit board, methods such as the toothbrush method, screen method, needle method, solder sucker, and pneumatic suction gun can be used.

Most simple methods for removing electronic components (including advanced pneumatic suction guns from abroad) are only suitable for single-sided boards and are not effective for double-sided or multi-layer boards.

Next, let's discuss double-sided PCB: To remove components from double-sided printed circuit boards, methods such as the one-sided overall heating method, syringe hollowing method, and solder flow welding machine can be used. The one-sided overall heating method requires a specialized heating tool, which is not universally applicable. The syringe hollowing method: First, cut off the pins of the component that needs to be removed, take off the component. At this point, what remains on the printed circuit board are the cut-off pins of the component. Then, use a soldering iron to melt the solder on each pin and use tweezers to remove them until all pins are removed. Finally, use a medical needle with an inner diameter suitable for the pad hole to hollow it out. Although this method involves a few more steps, it has no impact on the printed circuit board, is convenient to obtain materials, and is simple to operate, making it very easy to implement.

In the next article, we will discuss how to remove components from multi-layer PCB.