Let's continue to learn about the factors that affect the etching factor in ceramic PCB and how to adjust the etching factor to manufacture high-performance ceramic PCB.

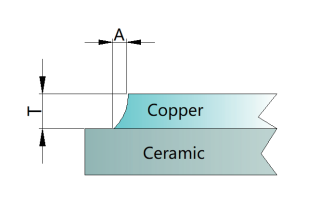

Factors affecting the etching factor include the composition, concentration, and temperature of the etching solution, as well as the thickness and surface area of the copper layer on the ceramic substrate.

Reducing the etching factor can enhance the durability and performance of DCB products. Specifically, by adjusting the photo tool design spacing to 0.43mm and increasing the etching line speed to 0.8250m/min, the etching factor can be effectively reduced to 2.19, which can increase the number of thermal shock cycles. This effectively improves the reliability of DBC ceramic substrates used in products such as semiconductor coolers, LED, and power semiconductors.

The above are all the tips regarding the etching factor in ceramic PCB. If you are also interested, you can place an order for ceramic PCB with our sales staff.