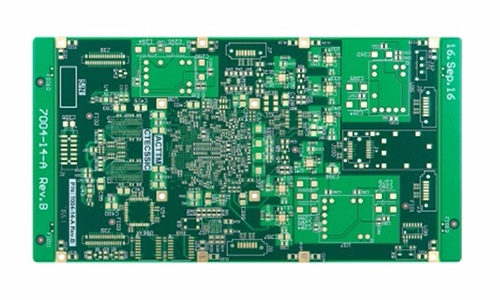

14-layer medical PCB circuit board is a high-performance printed circuit board designed for medical equipment.

Ultrasound Machine High-Level PCB Circuit Board Product Introduction

1.Product Overview

14-layer medical PCB circuit board is a high-performance printed circuit board designed for medical equipment. This product has excellent electrical performance and reliability, can meet the strict requirements of the medical industry for accuracy and stability, and is widely used in medical imaging equipment, monitoring instruments, diagnostic equipment and other fields.

2.Product Features

High-layer design

14-layer structure provides larger wiring space, supports complex circuit design and multi-signal transmission, and is suitable for high-density component layout.

Excellent electrical performance

The design optimizes signal integrity, reduces signal attenuation and crosstalk, and ensures stable transmission of high-frequency signals.

High-reliability materials

High-quality substrates (such as FR-4, polyimide, etc.) are used, with good thermal stability and chemical resistance, to meet the needs of medical environments.

Good thermal management

The design takes into account heat distribution, and uses heat dissipation holes and heat conduction materials to ensure stability under high-power working conditions.

Strict manufacturing standards

A manufacturing process that meets medical industry standards is used to ensure product quality and reliability.

3.Technical Parameters

| Number of layers | 14L | Minimum aperture | 0.25mm |

| Board thickness | 2.0mm | Minimum line width/line spacing | 0.1mm/0.1mm |

| Material | FR-4 SY1000-2 | Inner copper thickness | 18μm |

| Ink color | green oil with white characters | Outer copper thickness | 35μm |

| Surface treatment | ENIG | Minimum distance from hole to line | 0.2mm |

4.Application areas

Medical imaging equipment

Used in high-precision imaging systems such as CT, MRI, and ultrasonic equipment.

Monitoring instruments

Applied to real-time monitoring equipment such as ECG monitors and blood glucose monitors.

Diagnostic equipment

Applicable to laboratory analytical instruments, blood testing equipment, etc.

Implanted equipment

Used in implantable medical devices such as pacemakers and neurostimulators.

5.Design and Manufacturing Process

Requirement analysis

Communicate with customers to understand product requirements and technical specifications to ensure that the design meets medical standards.

Circuit design

Use professional software for circuit design to optimize signal paths and reduce interference.

PCB layout

Perform 14-layer layout and arrange the positions of circuit components reasonably to ensure signal integrity and power distribution.

Manufacturing

Use high-precision equipment for PCB production to ensure product quality and performance.

Testing and verification

Perform strict electrical performance testing and environmental adaptability testing on finished products to ensure compliance with design requirements and medical industry standards.

|

|

6.Summary

14-layer medical PCB circuit boards are an indispensable core component in modern medical equipment. With their superior performance and reliability, they have become an ideal choice for high precision and high stability in the medical industry. We are committed to providing customers with high-quality products and professional technical support to meet the needs of the evolving medical market.

FAQ

Q: Are the materials you use environmentally friendly?

A: The materials we use are in accordance with ROHS standard and IPC-4101 standard.

Q: How far is your factory from the nearest airport?

A: About 30 kilometers.

Q: Does the chemically plated palladium layer of nickel-palladium-gold PCB completely dissolve in the soldering process?

A: Yes, the chemically plated palladium layer completely dissolves in the solder during the soldering process.

Q: Can you do nickel-palladium gold processing?

A: Yes, we can.