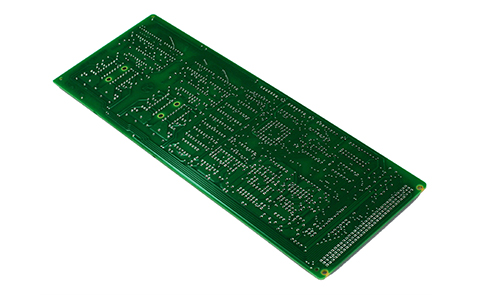

Double-sided medical PCB circuit board is a printed circuit board widely used in medical equipment with good electrical performance and reliability.

Raspberry PI Medical PCB Product Introduction

1.Product Overview

Double-sided medical PCB circuit board is a printed circuit board widely used in medical equipment with good electrical performance and reliability. This product is designed to meet the medical industry's requirements for high precision and high stability, and is suitable for a variety of medical equipment, such as monitoring instruments, diagnostic equipment, and portable medical devices.

2.Product Features

Double-sided design

Double-sided PCB design allows wiring on both sides, providing greater wiring space and flexibility, suitable for more complex circuit layouts.

Excellent electrical performance

Use high-quality materials and precision manufacturing processes to ensure the stability and integrity of signal transmission and reduce signal interference.

High reliability materials

Use substrates that meet medical industry standards (such as FR-4), have good thermal stability and chemical resistance, and adapt to various medical environments.

Good thermal management

The design takes into account heat distribution to ensure stability under high-power working conditions and prevent performance degradation caused by overheating.

Strict quality control

Strict quality control measures are implemented during the production process to ensure that each PCB meets the high standards of medical equipment.

3.Technical Parameters

| Number of layers | 2L | Minimum aperture | 0.7mm |

| Board thickness | 1.6mm | Surface treatment | tin spraying |

| Board material | FR-4 SY1141 | Minimum hole copper | 25um |

| Ink color | red oil with white characters | Copper thickness | 35um |

| Minimum line width/distance | 0.33mm/0.17mm |

4.Application Areas

Monitoring instruments

Used for real-time monitoring equipment such as ECG monitors and blood pressure monitors.

Diagnostic equipment

Suitable for laboratory analytical instruments, blood testing equipment, etc., supporting high-precision data acquisition and processing.

Portable medical equipment

Applied to portable ultrasonic equipment, mobile health monitoring equipment, etc., to meet the needs of portability and efficiency.

Implantable equipment

Used for certain non-invasive implantable devices to ensure long-term stable electrical performance.

5.Design and Manufacturing Process

Requirement analysis

Communicate with customers to understand product requirements and technical specifications to ensure that the design meets medical standards.

Circuit design

Use professional software for circuit design, optimize signal paths, and reduce interference.

PCB layout

Perform double-sided layout, arrange the positions of circuit components reasonably, and ensure signal integrity and power distribution.

Manufacturing

Use high-precision equipment for PCB production to ensure product quality and performance.

Testing and verification

Perform strict electrical performance tests and environmental adaptability tests on finished products to ensure compliance with design requirements and medical industry standards.

|

|

6.Summary

Double-sided medical PCB circuit boards are an indispensable core component in modern medical equipment. With their superior performance and reliability, they have become an ideal choice for high precision and high stability in the medical industry. We are committed to providing customers with high-quality products and professional technical support to meet the needs of the evolving medical market.

FAQ

Q: When can I get a quotation after I provide Gerber, product process requirements?

A: Our sales staff will give you a quotation within 1 hour.

Q: How many employees do you have in your factory?

A: More than 500.

Q: What is the primary role of the palladium layer in nickel palladium gold PCBs?

A: It prevents the migration of copper from the copper layer to the gold layer, which can lead to poor solderability.

Q: Can a lack of strict control during the production process lead to many problems?

A: In the production process, issues such as uneven plating thickness and inaccurate milling can negatively impact the performance of PCB. Therefore, strict control of the production process is key to ensuring quality.