2-layer medical PCB (printed circuit board) is a circuit board designed for medical equipment with high reliability and stability.

Double Sided PCB For Medical Product Introduction

|

|

1.Product Overview

2-layer medical PCB (printed circuit board) is a circuit board designed for medical equipment with high reliability and stability. They are widely used in various medical equipment such as monitors, diagnostic equipment, therapeutic instruments, etc.

2.Product Features

High reliability

Use high-quality materials to ensure stability in various environments.

After rigorous testing and certification, it meets medical industry standards.

Good electrical performance

Low resistance and low inductance design to ensure the stability of signal transmission.

Optimized layout design to reduce signal interference and noise.

High temperature and corrosion resistance

Use high temperature resistant materials to adapt to high temperature welding process.

Surface treatment can be optional gold plating, silver plating, etc. to enhance corrosion resistance.

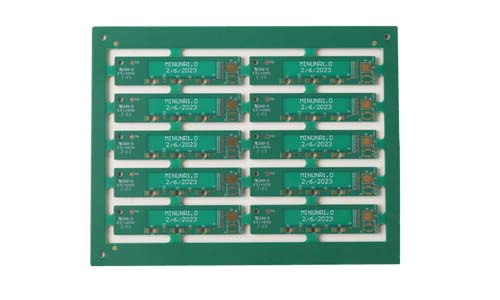

Compact design

2-layer structure makes PCB thinner and lighter, suitable for medical equipment with limited space.

It can realize the integration of multiple functions and reduce the number of components.

3.Application Field

Monitoring equipment

Used in ECG monitors, blood oxygen monitors, etc. to monitor patient vital signs in real time.

Diagnostic equipment

Including ultrasonic diagnostic equipment, X-ray machine, etc., to provide high-precision diagnostic results.

Therapeutic equipment

Such as laser therapy equipment, physical therapy equipment, etc., to help patients with treatment.

3.Technical specifications

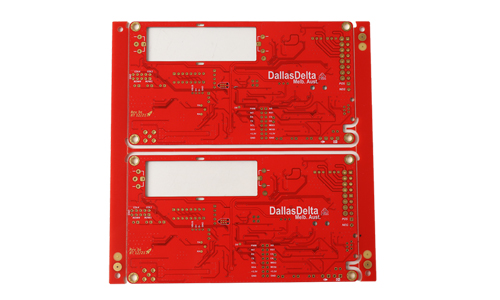

| Number of layers | 2 layers | Ink color | red oil and white text |

| Board thickness | 1.6mm | Minimum line width / line spacing | 0.1mm / 0.1mm |

| Material | FR-4 S1141 | Impedance control | ±10% |

| Copper thickness | 1oz / 1oz | Surface treatment | immersion gold |

4.Test Standard

Each board undergoes 100% electrical testing to ensure stable performance.

5.Manufacturing Process

Material selection

Common materials include FR-4, CEM-1, etc. to ensure the performance and durability of the circuit board.

|

|

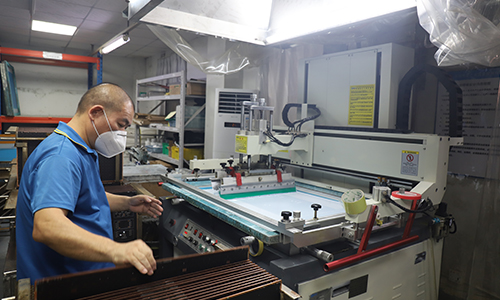

Printing process

Advanced screen printing and photolithography technology are used to ensure the accuracy of the circuit.

Assembly process

Surface mount (SMT) and through-hole mounting (THT) technologies are used to ensure the firmness and reliability of components.

6.Quality Control

Strict testing process

Including functional testing, withstand voltage testing, aging testing, etc., to ensure the quality of each PCB.

Compliance with international standards

Passed ISO13485 and other medical industry certifications to ensure that the products meet international medical device standards.

7.Conclusion

2-layer medical PCB circuit boards are an indispensable core component in medical equipment. With their high reliability and excellent performance, they provide a solid foundation for the development of the medical industry. Choosing the right manufacturer and materials can ensure the safety and effectiveness of medical equipment.

FAQ

Q: What is your minimum order quantity?

A: One piece is enough to place an order.

Q: When can I get a quotation after I provide Gerber, product process requirements?

A: Our sales staff will give you a quotation within 1 hour.

Q: Can a nickel-palladium-gold PCB withstand multiple lead-free reflow cycles?

A: Yes, a nickel-palladium-gold PCB can withstand multiple lead-free reflow cycles and has excellent gold wire bonding performance.

Q: Can you provide samples?

A: We have the ability to quickly proof-sample PCB and provide comprehensive technical support.