Four-layer ceramic PCB (Printed Circuit Board) is a high-performance circuit board that uses ceramic materials as substrates and has excellent electrical properties and thermal management capabilities.

Ceramic Substrate PCB Product Introduction

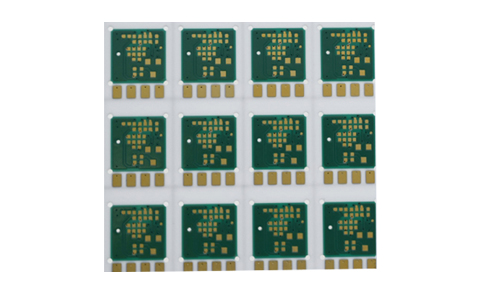

1.Product Overview

Four-layer ceramic PCB (Printed Circuit Board) is a high-performance circuit board that uses ceramic materials as substrates and has excellent electrical properties and thermal management capabilities. It is widely used in electronic equipment in high-frequency, high-power and high-temperature environments, especially in the fields of communications, medical, automotive and aerospace.

2.Main Features

Excellent thermal conductivity:

Ceramic materials have high thermal conductivity and can effectively dissipate heat, suitable for high-power applications.

High electrical insulation:

Ceramic substrates provide excellent electrical insulation performance to ensure the stability and safety of the circuit.

High temperature resistance:

Able to work for a long time in high temperature environments, suitable for harsh working conditions, and can usually withstand temperatures exceeding 200°C.

Good mechanical strength:

Possessing high impact and pressure resistance, suitable for various application scenarios.

Low dielectric constant and low loss:

Suitable for high-frequency signal transmission, reducing signal attenuation and improving signal integrity.

3.Technical Parameters

| Number of layers | 4 | Minimum line width | 0.065mm |

| Material | Alumina (Al2O3) | Minimum line spacing | 0.065mm |

| Ceramic process | Immersion gold | Minimum drilling | 0.15mm |

4.Structure

Four-layer ceramic PCB usually consists of the following layers:

First layer: signal layer, responsible for transmitting electrical signals, usually using metallized hole technology to connect the layers.

Second layer: power layer, providing power distribution to ensure stable power supply of the circuit.

Third layer: ground layer, enhancing the anti-interference ability of the circuit and providing good electrical performance.

Fourth layer: bottom layer, providing mechanical support and protection to ensure the stability of the overall structure.

5.Application Areas

Communication equipment: such as base stations, routers, RF modules, etc.

Automotive electronics: such as control systems, sensors and drive circuits of electric vehicles.

Medical equipment: such as high-precision medical instruments, monitoring equipment, etc.

Aerospace: such as electronic systems and control modules of satellites and aircraft.

|

|

6.Conclusion

Four-layer ceramic PCB circuit boards have become an indispensable material in modern electronic devices due to their excellent performance and reliability. With the continuous advancement of science and technology, its application areas will continue to expand, providing more efficient and reliable solutions for various industries.

FAQ

Q: How far is your factory from the nearest airport?

A: About 30 kilometers

Q: What is your minimum order quantity?

A: One piece is enough to place an order.

Q: How much does a PCB ceramic board cost?

A: The cost of a ceramic PCB board is significantly higher than that of a traditional PCB board. Ceramic boards are much more expensive than FR4 boards, so the price of ceramic PCB is substantially higher, generally more than three times that of traditional PCB. The cost of prototyping ceramic PCB also differs from that of mass production, with mass production being more cost-effective.

Q: How to quote a ceramic PCB?

A: The specific quotation depends on the drawings, process requirements, complexity, and the utilization rate of the ceramic substrate. Generally, aluminum nitride ceramic PCB are more expensive than alumina ceramic PCB due to their superior thermal conductivity. However, the exact quotation is subject to the evaluation of the provided data files.

Q: Can you provide samples?

A: We have the ability to quickly proof-sample PCB and provide comprehensive technical support.