As we all know that, FR-4 and aluminium-base material are common raw materials in PCB manufacture. Do you know what’s the difference between them? Today let’s learn about that.

Let’s start from their definition:

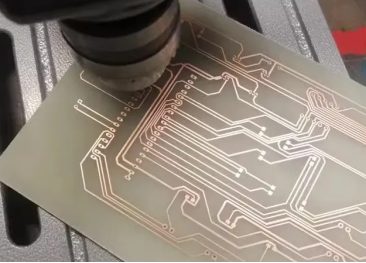

Aluminum baseboard is a metal-based board with aluminum as its core material. An insulating layer, typically made of a specific insulating material, is plated on the aluminum base material to ensure the insulation and safety of the circuit. Above the insulating layer, conductive layers are plated to form the conductive patterns on the circuit board. Aluminum baseboards are widely used in applications requiring efficient heat dissipation, such as LED lighting and power electronics, due to their excellent thermal conductivity.

FR-4 (Flame Retardant 4) is a glass fiber-reinforced epoxy resin laminate composed of multiple layers of glass fiber cloth and epoxy resin. FR-4 is the most commonly used substrate material for PCBs due to its good electrical insulation, mechanical strength, and processing performance. It is widely used in various electronic products, especially in applications where high thermal conductivity is not required.

In the next article, we will focus on comparing the differences in thermal conductivity and mechanical strength between aluminum baseboards and FR-4. The performance comparison of these two materials is crucial for selecting the appropriate PCB substrate material.