In the production and manufacturing of PCB, the production principles of thick copper PCB mainly revolve around their needs to carry high current, high power, and high reliability. Here are the key principles for the production of thick copper PCB:

1. Substrate Selection: Thick copper PCB usually use high-temperature materials such as FR4 or CEM-1 as substrates to ensure reliability in high-power applications.

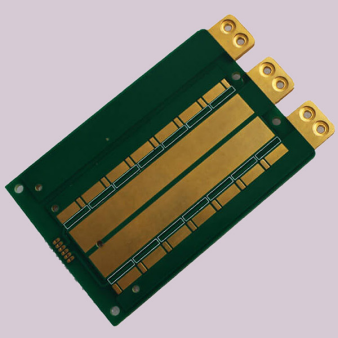

2. Copper Foil Thickness: The copper layer thickness is usually more than 3 ounces (about 70 microns) to improve the circuit's current-carrying capacity and thermal management performance.

3. Graphic Transfer: The design pattern is precisely transferred to the copper foil through photolithography processes, preparing for subsequent etching processes.

4. Acid Etching: Remove the copper layer not protected by the photoresist pattern, retaining the required circuit graphics. Due to the thicker copper foil, longer etching times and stronger etching solutions may be required.

5. Electroplating: After graphic etching is completed, electroplating is carried out to increase the copper layer thickness, ensuring that the PCB meets the requirements of high current and high-power applications.

6. Surface Treatment: The PCB surface is treated by methods such as hot air leveling, lead-free spray tin, or nickel gold to prevent oxidation and corrosion of the copper circuit.

7. Multilayer Pressing: For multilayer thick copper PCB, the lamination process requires special treatment to fill the gaps between copper layers and ensure good interlayer adhesion.

8. Drilling and Through-Hole Plating: After drilling, through-hole plating is carried out to ensure electrical connection and structural stability between layers.

9. Multiple Etching and Plating: Due to the thicker copper layer, multiple etching and plating may be required to achieve the desired precision and thickness.

10. Reliability Testing: After production is completed, strict reliability tests are conducted to ensure the performance and lifespan of thick copper PCB under high current and high power conditions.

These principles ensure the performance and reliability of thick copper PCB in high-demand applications.