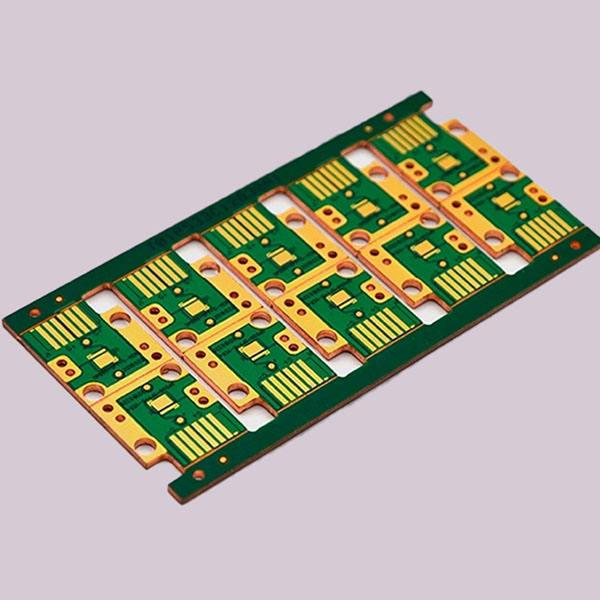

Thick copper PCB, which refers to printed circuit boards with copper foil thickness greater than 3 ounces (3oz), is known for its superior electrical performance, enhanced mechanical strength, and excellent thermal performance. This special PCB design can meet the application requirements under high current, high power, and harsh environmental conditions.

The main advantage of thick copper PCB is its ability to support high current, high temperature, and repeated thermal cycling frequencies, which can harm ordinary circuit boards within seconds. In addition, there is a large demand for thick copper PCB circuit boards in computers, automobiles, military, and industrial control.

Thick copper PCB, due to their higher copper foil thickness compared to ordinary PCB, have better thermal conductivity and current carrying capacity. This makes them particularly important in high power and current applications in fields such as power supplies, welding equipment, distribution, power converters, solar panel equipment, medical, automotive, and aviation, as the thick copper layer helps to control heat dissipation and operate high power and current. The high current capacity, thermal strain tolerance, heat dissipation performance, and mechanical strength at connectors and PTH holes of thick copper PCB have been significantly improved, helping to reduce product size and enhance overall performance.

In the next article, we will detail the advantages of thick copper PCB over ordinary PCB.