PCB Green Oil Solder Mask

Generally speaking, green oil PCB is widely and widely used for the following reasons:

1.From the function, green ink added to the composition has long been fixed, basically the

equipment potion is for green, easy to develop, not easy to come off.

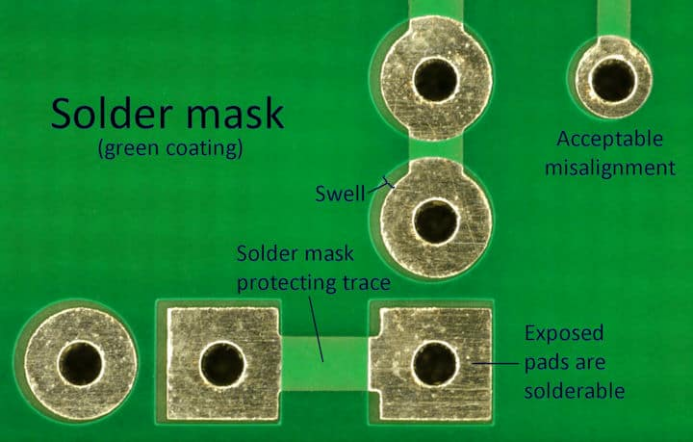

2.On the appearance of the inspection, green ink and copper surface (yellow) contrast is obvious, it is easier to detect scratches, deflections and other defects. And other miscellaneous colors oil are added to change the colour of some of the powder material. For PCB production is relatively high cost. But for the finished product, some colors look more high-end than green. In addition, there are manual visual inspection in the PCB quality control process, green is more eye-catching, and more friendly to the visual inspection staff.

3.Green ink can do smaller error, smaller area, can do higher precision, green, red, blue than other colors have a higher design accuracy.

4.Green ink has better characteristics than other colors. Especially the green hole plugging characteristics.

5.Green ink is relatively lower cost. Due to the production process, green is the mainstream, naturally the procurement of green ink will be greater, so its procurement cost relative to other colors will be lower.

6.Many PCB ink manufacturers in order to reduce costs, but also mass production of green oil, which also contributes to the price of green oil will be lower.

7.PCB processing, electronics production, including boards and SMT, during which there are several processes to go through the yellow room, and the green PCB board in the yellow room has the best visual effect.

8.In the SMT chip processing, applying solder paste, patch and AOI calibration of these steps, all need optical positioning calibration, green PCB instrument recognition is more friendly.

9.Green PCB is also more environmentally friendly, the waste board for high-temperature recycling process, will not release toxic gases.

10.Other PCB colors, such as blue and black doped with cobalt and carbon, respectively, because there is a weak conductivity, there will be a short circuit risk. In addition, like black, purple, blue lights, PCB substrate colour is too dark, it will increase the difficulty of inspection and maintenance of the motherboard, the process is not good control.