Today we will continue to learn about the influence of red ink test in PCB manufacture.

We will start from detecting solder joint integrity

Detecting Solder Joint Integrity:

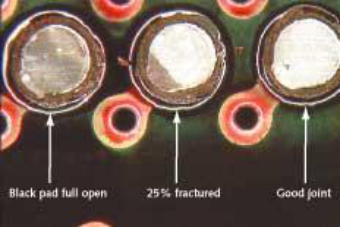

A key function of the Red Ink Test is to detect the integrity of solder joints. During the soldering process, solder joints may develop cracks or voids due to various reasons, which may not be easily detected by visual inspection. By immersing the PCB in red dye, if the solder joint is intact, the dye will not penetrate into the interior of the solder joint; if the solder joint has cracks or voids, the dye will penetrate into the interior of the solder joint, thereby detecting the integrity of the solder joint. This method can effectively identify minor defects in solder joints, ensuring soldering quality.

Next, let’s learn about the detecting solderability.

Detecting Solderability:

The Red Ink Test can also be used to detect the solderability of the PCB surface. Solderability refers to the ability of the PCB surface to bond well with solder. If the solderability of the PCB surface is good, the red dye will evenly cover the PCB surface; if the solderability of the PCB surface is poor, the red dye will not evenly cover the PCB surface, thereby detecting the solderability of the PCB surface. This detection helps to identify welding problems caused by improper surface treatment or contamination

In the next article, we will learn another important influence of red ink test.