Today, we will learn about the main materials which are maked into SMT Stencil.

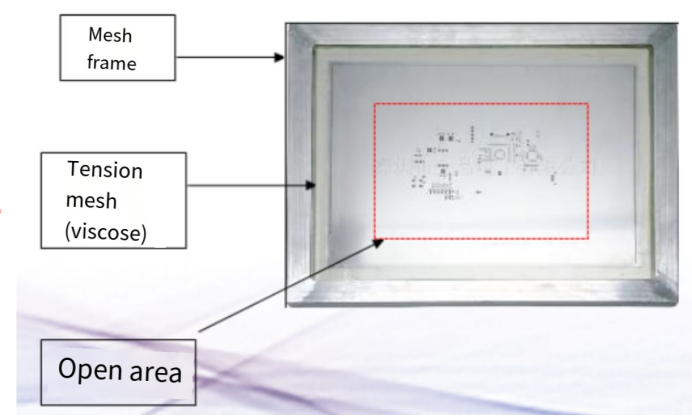

The SMT stencil is primarily composed of four parts: the frame, mesh, stencil foil, and adhesive (viscose). Let's analyze the function of each component one by one.

1. Frame

Frames can be divided into removable and fixed types. Removable frames directly mount the steel sheet onto the frame, allowing for repeated use of a single frame. Fixed frames use adhesive to bond the mesh to the frame, which is then further secured with glue. Fixed frames are more likely to achieve uniform steel sheet tension, typically ranging from 35 to 48 N/cm². (The allowable tension for a standard fixed frame is 35 to 42 Newtons.)

The frame size is determined by the requirements of the solder paste printer, with examples such as the DEK 265 printer and the MPM printer model UP3000, which use a frame size of 29" x 29" (735 x 735 MM) made of aluminum alloy, with a frame profile specification of 1.5" x 1.5". For semi-automatic solder paste printers, the frame size is approximately 22" x 26" (560 x 650 MM). Basic stencil models: (CM) 20*30, 30*40, 37*47, 42*52, 50*60, 55*65, 23"*23", 29"*29". Common thicknesses: (MM) 0.05 (rarely used), 0.08 (rarely used), 0.10, 0.12, 0.13, 0.15, 0.18, 0.20, etc.

2. Mesh

Mesh is used to secure the steel sheet and frame and can be divided into stainless steel wire mesh and high polymer polyester mesh. Stainless steel wire mesh commonly uses around 100 mesh, providing a stable and sufficient tension, but it can deform and lose tension over extended use. Polyester mesh, made of organic material, also commonly uses 100 mesh and is less prone to deformation, offering a longer service life.

3. Stencil Foil

The selection of SMT stencil template materials must consider factors such as the material's rigidity, corrosion resistance, ductility, and coefficient of thermal expansion, as they directly affect the stencil's service life (rust, distortion, and deformation of mesh holes). Common stencil template materials include tin phosphor bronze, stainless steel, and nickel-chromium alloys, with stainless steel being the most common. These are used to create apertures in copper, stainless steel, nickel alloys, and polyester materials. Stencils generally use high-quality 301/304 stainless steel sheets from abroad, which, with their excellent mechanical properties, greatly increase the service life of the stencil.

4. Adhesive

The adhesive used to bond the frame and steel sheet plays a significant role in the stencil. It is specifically chosen based on the customer's usage situation. This adhesive maintains a strong bond and can resist the complex cleaning processes involving various stencil cleaning agents.

In the next article, we will discuss the manufacturing requirements for PCB SMT stencils.