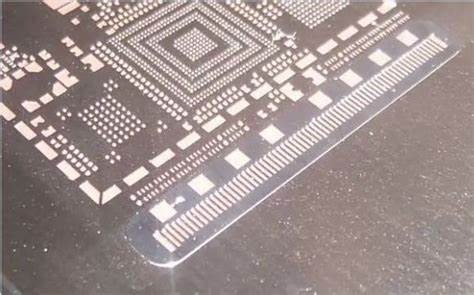

Today we will introduce the Classification of SMT Stencils from usage, process, and material.

By usage:

1. Solder Paste Stencil: A stencil used for depositing solder paste onto PCB pads for surface-mount components.

2. Adhesive Stencil: A stencil designed to apply adhesive for components that require it, such as certain types of connectors or heavy components.

3. BGA Rework Stencil: A specialized stencil used for the rework process of BGA (Ball Grid Array) components, ensuring precise adhesive or flux application.

4. BGA Ball Planting Stencil: A stencil used in the process of attaching new solder balls to a BGA component for reballing or repair.

By process:

1. Etched Stencil: A stencil created through a chemical etching process, which is cost-effective for simpler designs.

2. Laser Stencil: A stencil produced using a laser cutting process, offering high precision and detail for complex designs.

3. Electroformed Stencil: A stencil made by electroforming, which creates a three-dimensional stencil with excellent step coverage for fine pitch devices.

4. Hybrid Technology Stencil: A stencil that combines different manufacturing techniques to leverage the advantages of each for specific design requirements.

By material:

1. Stainless Steel Stencil: A durable stencil made from stainless steel, known for its longevity and resistance to wear.

2. Brass Stencil: A stencil made from brass, which is easier to etch and offers good wear resistance.

3. Hard Nickel Stencil: A stencil made from hard nickel, providing excellent durability and precision for high-quality printing.

4. Polymer Stencil: A stencil made from a polymer material, which is lightweight and offers flexibility for certain applications.

Next we will learn some terms about PCB SMT Stencil.