Today, we will delve into the material property classification of IC substrates. Due to the diverse functionalities of integrated circuits, their substrates require different material types and characteristics to meet specific performance demands.

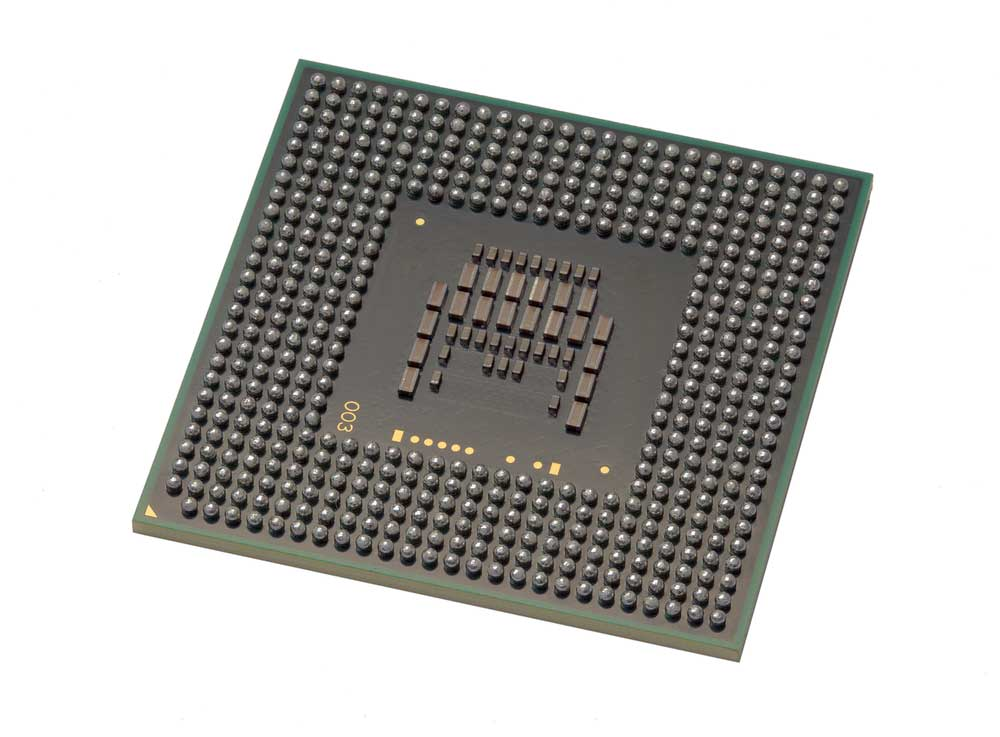

1. Rigid substrates: These types of substrates are typically made from resin materials, including Ajinomoto Build-up Film (ABF), epoxy resins, or bismaleimide triazine (BT) materials. These materials are widely used for their excellent mechanical strength and electrical insulation properties.

2. Flexible substrates: The manufacturing of flexible substrates often employs polyimide or polyamide resins, which not only offer good electrical performance but also have a thermal expansion coefficient matched to silicon chips, contributing to the reliability of the packaging.

3. Ceramic substrates: Ceramic substrates are favored for their superior thermal conductivity and chemical stability, with common materials including aluminum nitride, silicon carbide, or aluminum oxide. These materials can maintain performance in extreme temperature and chemical environments, making them suitable for high-performance computing and power electronics applications.

These are the three main classification methods for IC substrates, and the next article will detail the application fields where IC-bearing PCBs are used.