So let’s continue to talk about which parts and components that can’t be covered by conformal coating.

In PCB manufacturing, there are certain parts and components that should not be coated with conformal coating, including:

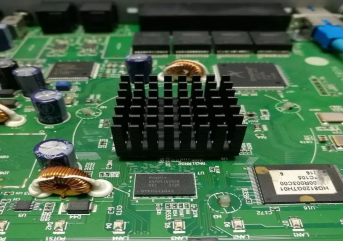

1. Heat dissipation related components:

High-power heat sinks, heat sinks, power resistors, etc., which require effective heat conduction and can be hindered by conformal coating.

2. Specific resistance components:

Cement resistors, etc., which have special heat dissipation or performance requirements and are not suitable for conformal coating.

3. Electrical connection and adjustment components:

Dip switches, potentiometers (variable resistors), etc., which need to maintain flexibility and adjustability.

4. Sound and display components: Buzzers, digital tubes, etc., which need to maintain unobstructed transmission of sound or light.

5. Power and protection components: Battery holders, fuse holders, etc., which need to be easily replaceable and maintainable.

6. Interface and connection components: IC sockets, tactile switches, relays, and other sockets, pins, terminal blocks, as well as DB9 and other interfaces, which need to maintain reliable contact.

7. Light-emitting diodes (LED): Non-indicative through-hole or surface-mount LEDs, which need to maintain light transmission.

8. Grounding components: Grounding screw holes, which need to maintain good electrical connection.

In addition, it includes parts and components that customers specifically indicate should not use conformal coating in their drawings, as well as components that are clearly mentioned not to use conformal coating according to the "The Catalogue of Components (Parts) Not to Be Coated with Conformal Coating".