In the PCB design and manufacturing industry, after engineering designers complete the PCB design, they need to conduct a series of checks to ensure the correctness and manufacture ability of the design. These checks are crucial to ensure that the PCB design meets specific specifications and manufacturing requirements.

DRC Check (Design Rule Check):

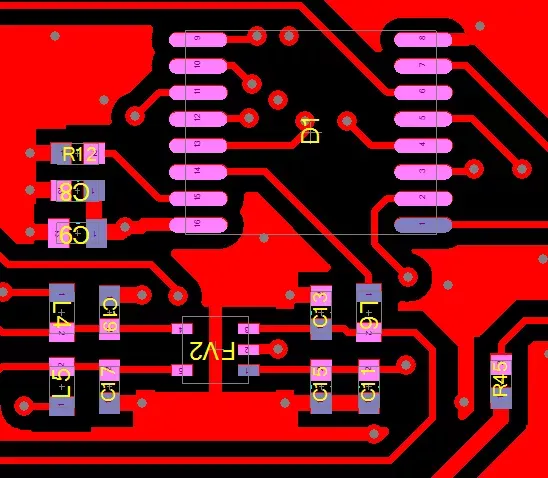

DRC check, or Design Rule Check, is a feature in PCB design software (EDA tools) that allows for real-time checking and identification of design issues that do not comply with predetermined design specifications during the PCB layout process. The main purpose of DRC is to ensure the correctness of the design and to ensure that it meets conventional design specifications. It is an indispensable part of PCB design because even the smallest design errors can lead to the failure of the entire circuit board or production difficulties.

The items checked by DRC typically include, but are not limited to: line width, line spacing, pad size, hole size, inter layer insulation, coefficient of thermal expansion matching, etc. The number of these check items generally does not exceed 100, but varies depending on specific design requirements and manufacturing capabilities. DRC helps designers identify and correct potential design issues, thereby improving the quality of PCB design and the success rate of production.

In the next article, we will introduce DFM check (Design for Manufacture ability), which is a method focused on improving the manufacture ability of PCB. It involves assessing the PCB design from a manufacturing perspective to determine if it is suitable for the production process and how to optimize the design to reduce manufacturing costs and improve production efficiency.