We have introduced the PCB solder mask, so what is the PCB paste mask?

Paste mask. It is used for the SMT (Surface-Mount Technology) placement machine to place components. The template of the paste mask corresponds to the pads of all surface-mounted components, and its size is the same as the top and bottom layers of the board. It is prepared for the process of creating the stencil and solder paste printing.

In the context of PCB manufacturing processes, solder mask and paste mask have distinct roles.

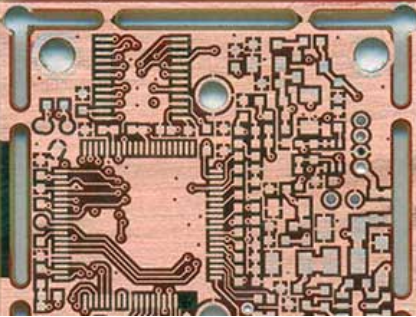

Solder Mask, also known as the green oil layer, is a protective layer applied to the copper surfaces of a PCB where soldering is not required. Its primary function is to prevent solder from flowing into non-soldering areas during the assembly process, thereby avoiding shorts or poor solder joints. Solder mask is typically made from epoxy resin, which protects the copper circuits from oxidation and contamination, and enhances the insulation properties of the PCB. The color of the solder mask is commonly green, but it can also be blue, black, white, red, etc. In PCB design, the solder mask is usually represented as a negative image, meaning that after the mask's shape is transferred to the board, it is the copper that is exposed.

Paste Mask, also referred to as the solder paste layer or stencil layer, is used during the Surface-Mount Technology (SMT) process. The paste mask is used to create a stencil, and the holes in the stencil correspond to the solder pads on the PCB where Surface-Mount Devices (SMDs) will be placed. During the SMT process, solder paste is printed through the stencil onto the pads of the PCB to prepare for component attachment. The paste mask is sized to match the dimensions of the solder pads, ensuring that the solder paste is applied only where needed for component soldering. The paste mask helps to accurately deposit the right amount of solder paste for the soldering process.

In summary, the solder mask is designed to prevent unwanted soldering and protect the PCB, while the paste mask is used to apply solder paste to specific areas to facilitate the soldering process. Both are essential in PCB manufacturing, but they serve different purposes and are used in different contexts.