Today, we will continue to learn about the factors that determine how many layers a PCB is designed to have.

Firstly, the issue of operating frequency must be taken into account. The parameters of the operating frequency determine the functionality and capacity of the PCB. For higher speeds and operational capabilities, multilayer PCBs are essential.

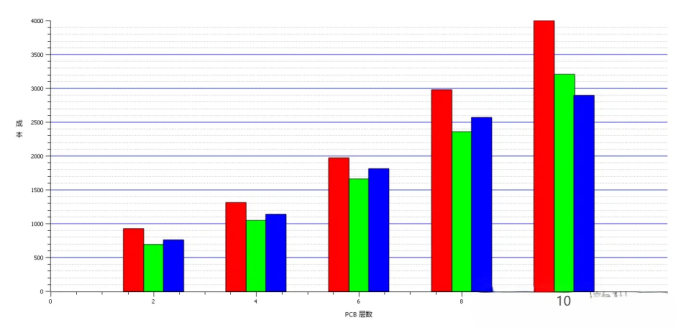

Secondly, the factor to consider is the manufacturing cost of single-layer and double-layer PCBs compared to multilayer PCBs. If you want a PCB with the highest possible capacity, the cost you need to pay will inevitably be relatively higher. The design and manufacture of multilayer PCBs will be longer and more expensive. The cover diagram shows the average cost of multilayer PCBs from three other manufacturers in the industry:

The cost standards for the chart are as follows: PCB order quantity: 100; Printed circuit board size: 400 mm x 200 mm; Number of layers: 2, 4, 6, 8, 10.

Of course, the cost estimation bar chart in the above figure is not absolute, and Sanxis Company will help customers evaluate the cost of their PCB when they place an order, choosing different parameters such as conductor type, size, quantity, number of layers, substrate material, thickness, etc. If you want to know more in detail, please contact our sales staff to place an order.

In the next new, we will continue to talk about the other factors that determine how many layers a PCB is designed to have.